SEDİROGLU INTERNATIONAL MACHİNE ABOUT US

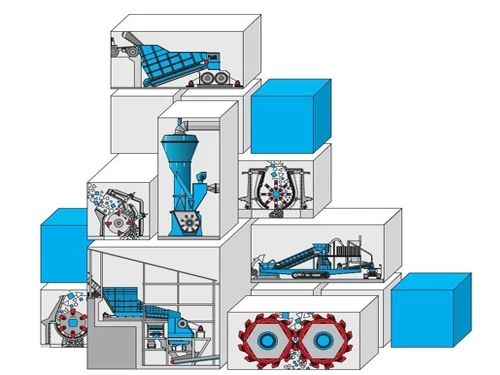

As SEDİROGLU INTERNATIONAL MACHİNE, we are taking solid and reliable steps towards becoming a corporate by bringing together our experience and experience in the fields of manufacturing, project and management. Our company will always be at the service of our valued customers with its experienced staff and modern technical equipment in the machinery production sector. Stone crushing and screening facilities not only break materials such as stones or rocks into smaller sizes, but also provide a full-fledged environment. In these facilities, rocks with various hardness levels are broken and those of similar sizes are grouped. This grouping process is called elimination. Optional components such as crusher machines, screens and cement silos work in complete harmony.

Stone and rock crushing plant machinery plays an important role in industries such as construction, mining and quarries. These machines are used to break large stones into small pieces and obtain granules of different sizes. Stone crushing plant machines accelerate work processes, increase efficiency and ensure quality. In this article, information about the types and advantages of stone crushing plant machines is as follows.

By combining technical knowledge with years of experience, transferring it to new generations and improving its production, SEDİROGLU INTERNATIONAL MACHİNE continues to serve as a company that supports its work. These are quarry lands, which are called crushers and are one of the main working areas of crusher machines. Although second-hand products are relatively more cost-effective, new products have a higher profit rate in the long run. One reason for this is that brand new products can operate at high performance values for a much longer period of time. Our recommendation is definitely brand new machines.

Stone crushing machines work according to different principles. These machines also have different technical features and equipment. The reason for this is that it can be offered in machines that can appeal to different user categories. The prices of machines working on different principles may also be different. Stone crushing machines are classified under three headings according to their working conditions and principles.

• Jaw crusher: These crushers crush the material between two plates, one of which is fixed and the other is movable. These machines, which work almost like a strong human jaw structure, take their name from the relevant anatomical structure.

• Cone crusher: This type of crusher breaks the material by compressing or cutting it. Thus, it is possible to produce materials in desired dimensions.

• Impact crusher: It shrinks the materials by impact instead of pressure. They are extremely suitable and safe machines for recycling the debris resulting from demolition activities.

Our aim is to provide high-quality, reliable design and production for the Turkish and World Crushing, Screening and Washing Machinery industry sectors with its high-tech benches, equipment, software and hardware, and talented, knowledgeable and experienced personnel. It is one of our basic principles to serve our country and the world by establishing and operating quality with pre-sales, after-sales and spare parts services. Some of the advantages of stone crushing plant machines are:

• High efficiency: Stone crushing plant machines also increase production efficiency by processing large volumes of stones quickly. In this way, business processes are accelerated and more products are obtained.

• Quality control: The precise adjustability features of the machines enable the desired granule sizes to be obtained. This is important to control product quality and offer products that meet customer requirements.

• Cost savings: Stone crushing plant machines operate more efficiently and effectively compared to manual labor. This allows businesses to save on labor costs. They also help to reduce energy costs economically with low energy consumption.

• Workmanship safety: Stone crushing plant machines also ensure the safety of workers working in dangerous and difficult working conditions. It significantly reduces the risk of work accidents and injuries by reducing human intervention and physical strain.

• Reducing environmental impacts: Modern stone crushing plant machines are equipped with environmentally friendly technologies. Features such as dust extraction systems, noise control and optimizing water use play an important role in minimizing environmental impacts.

SEDİROGLU INTERNATIONAL MACHINE, OUR PRIORITY IS TO PROVIDE TRUST

SEDİROGLU INTERNATIONAL MACHİNE, one of the world's leading companies in its sector, competes for leadership in this field with its future vision. By using the opportunities offered by technology, it is especially effective in making decisions based on data. The main and most important factors that make us different are the importance we attach to tolerance and solidarity, which we need to be aware of social responsibility and understanding of transparency, and our responsibility towards the environment. A crusher plant can also perform screening and washing duties for an important building material such as sand. Sand can be dirty to a certain extent depending on the method it is obtained from and the area where it is collected. Purification and cleaning of the sand is carried out with the help of sieves that also have a washing feature. Please contact us to get comprehensive and detailed information about sand screening and stone crushing machines prices and to request an order. Best regards.