-

Feature of The Product

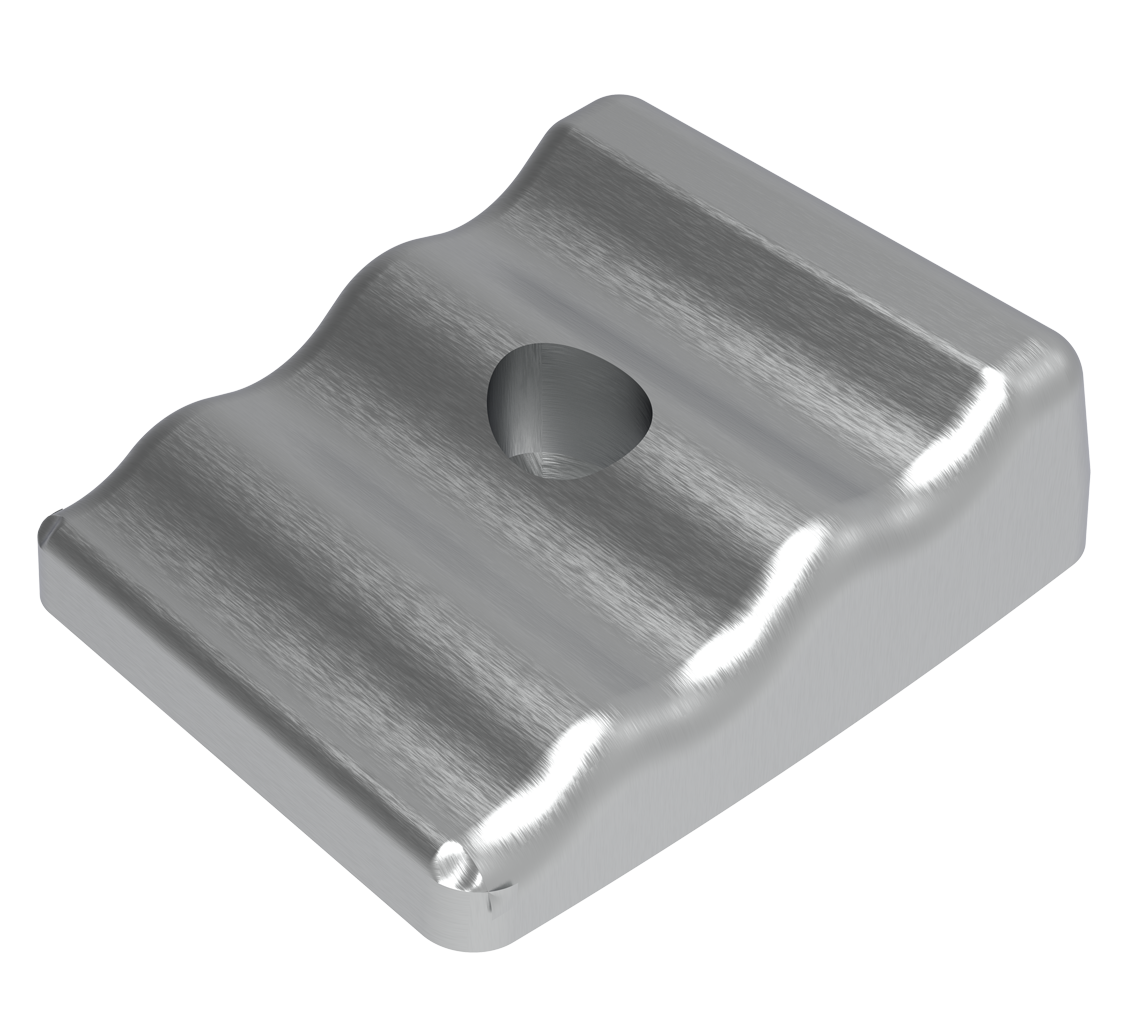

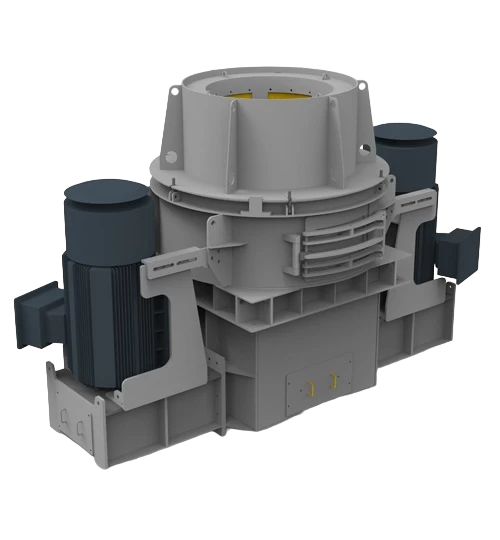

Crusher Cone Module

The Crusher Cone Module SE-TO-KNK cone module features the spider bearing cone on the same universal base structure as the KNK and KN Series modular lines. The pre-engineered solution can be easily transportedin standard containers and can be assembled on- site quickly with minimal wiring. The bronze bushing technology of the Crusher Cone Module SE-TO-KNK 5100 cone enables the operator to quickly and easily alter the eccentric throw of the cone, on site, simply by rotating the eccentric bushing.

-

Feature of The Product

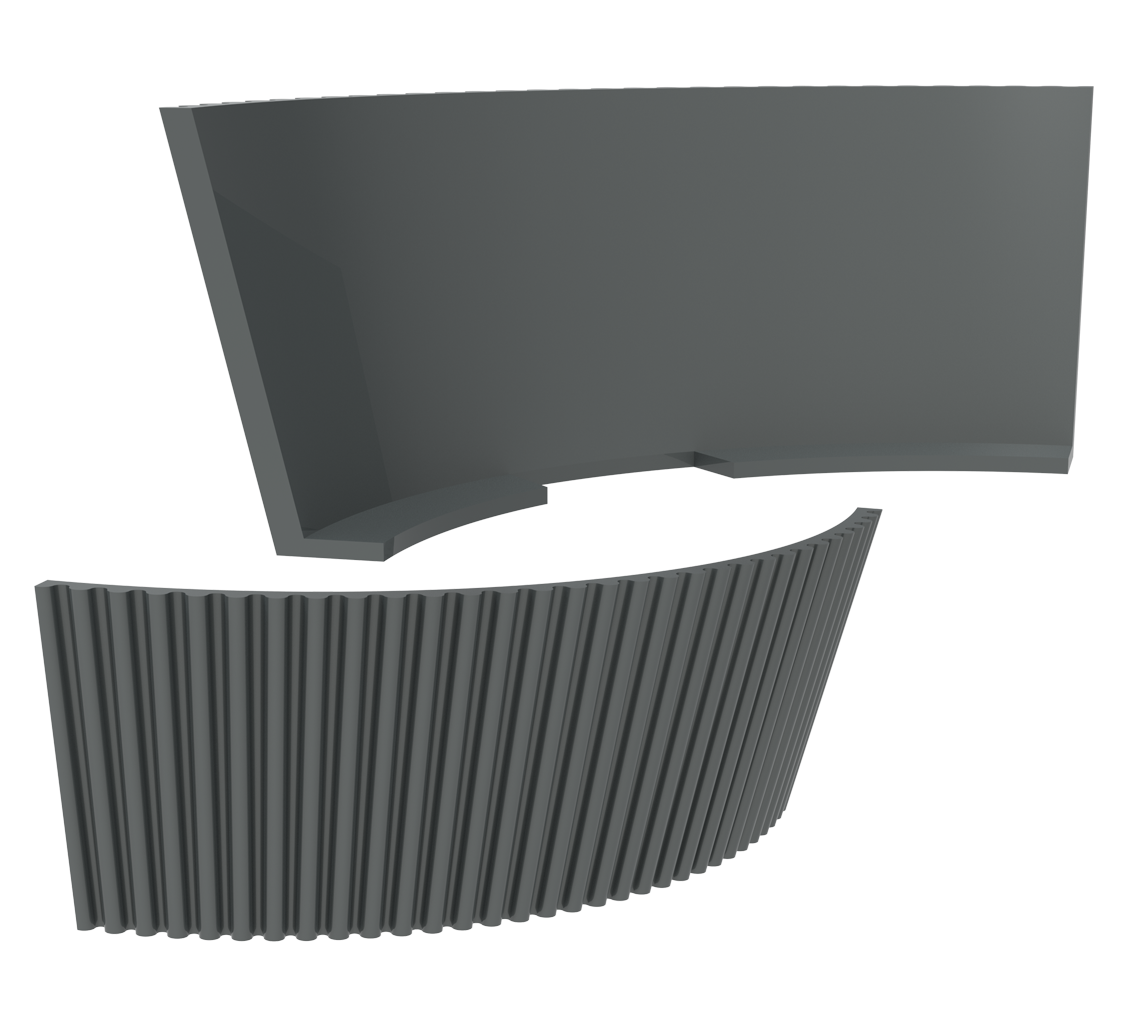

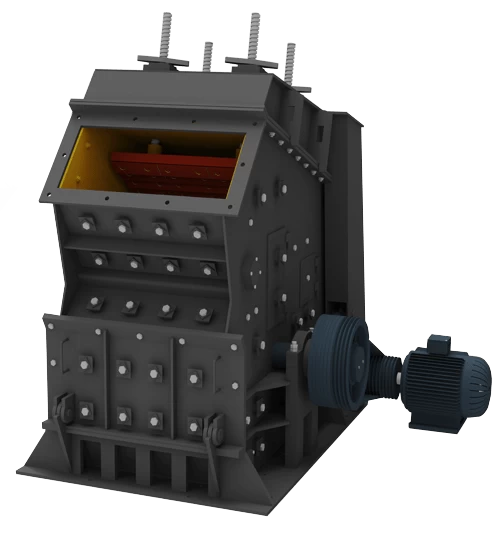

Secondary Impact Crusher Module

SE-TO-KNA - Secondary Impact Crusher Module series secondary crushers are our secondary impact crushers, which are generally used after jaw crushers or primary impact crushers, leading to the crushing of medium and high hardness materials. SE-TO-KNA crushers are designed to reduce wear costs while increasing capacity and cubic product volume.

Announcement and text sharing

45+

Years of Experience

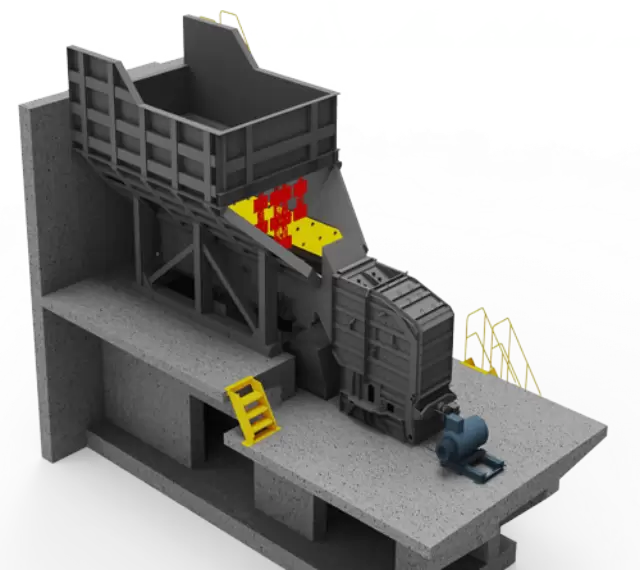

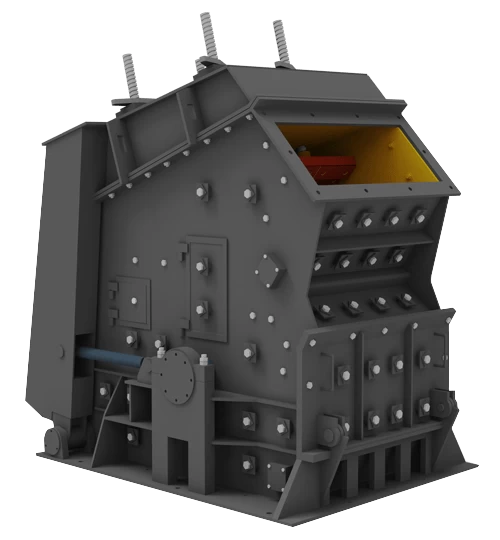

Primary Impact Crusher

Working Principle

Primary Impact Crusher is a crusher model specially designed to handle large feed sizes and high capacity crushing. Primary Impact Crusher impact crusher is used for primary processing of limestone materials or medium hard materials.

Primary Impact Crusher can be used instead of the jaw crusher model when the fed material is not particularly hard and abrasive, because in addition to the high particle size reduction rate, it provides a higher proportion of fines. The maximum feed size is designed depending on the size of the feed opening.

Vertical Shaft impact Crushers

The Vertical Shaft Crusher machine is designed as a machine that can be used in sand quarries, ready-mixed concrete and mining industries. The Vertical Shaft Crusher has low maintenance requirements and a long working life. Vertical shaft crusher is used to obtain 0.5 mm sand by breaking basalt, granite, or rock or any similar abrasive materials. Vertical Shaft Crusher is also used extensively in shaping soft stones or removing aggregate, crushing cement clinker before mills and glass recycling facilities. is used.

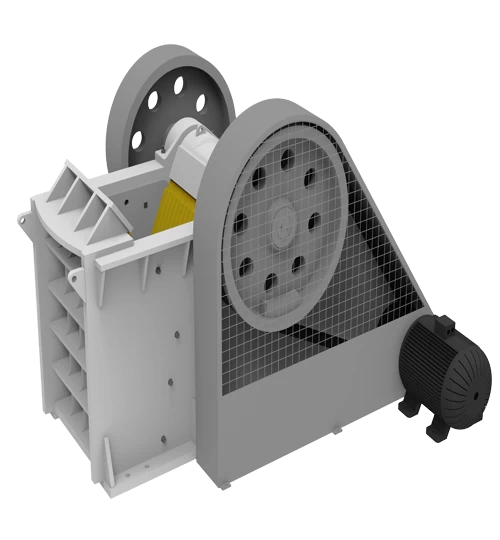

Jaw Crusher

Jaw crusher is a machine that allows materials such as stones and rocks of different hardnesses to be easily broken. In addition, it is considered one of the low-cost crusher types that can be easily maintained and overhauled. Thanks to the high pressure force it applies, the jaw crusher enables stones and rocks of all hardnesses to be easily broken. With the effect of the mechanical pressure and power it applies, the moving jaw breaks stones and rocks with the impact of the impact force on the jaw in a fixed position. Jaw crusher provides the opportunity to break the stones and rocks in desired sizes.

Would you like to contact us?

Don't hesitate to call us for information about the product you need.

Check out our latest blog posts and news.

Optimizing Furnace Cast Parts for Maximum Efficiency

Explore strategies for optimizing furnace cast parts to reduce wear and increase productivity.

Understanding Wear Resistance in Cement Plant Cast Parts

Learn how wear-resistant cast parts extend the life of cement plant components.

Optimizing Aspirator Performance in Cement Plants

Well-maintained aspirators improve cement quality, reduce dust, and enhance overall plant efficiency.