- Sediroglu

- 17 January 2025

Technical specifications of chain mill

SEDİROGLU İNTERNATİONAL Chain Mill: Revolutionizing Material Processing with Efficiency and Precision

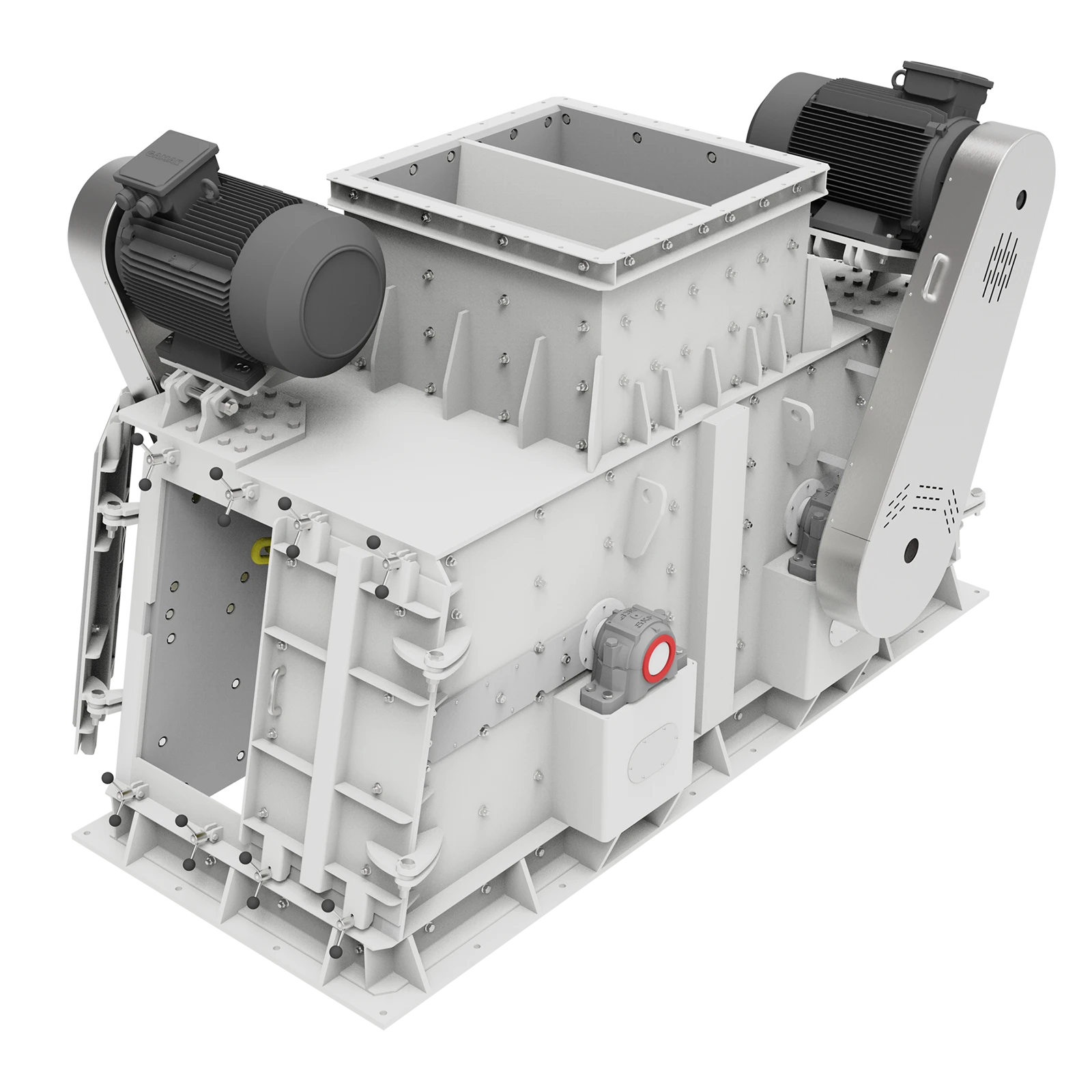

A Chain Mill is a highly efficient and versatile crushing machine designed to meet the demands of industries requiring reliable material processing solutions. From fertilizer production to chemical processing, this machine has become an indispensable tool in modern industrial workflows. Its unique design, featuring high-speed rotating chains, ensures precise material breakdown, making it a valuable asset in various applications.

What is a Chain Mill SEDİROGLU İNTERNATİONAL?

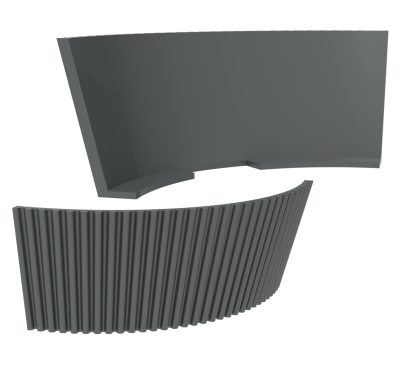

A Chain Mill operates by using chains to crush materials into smaller, uniform particles. This simple yet effective mechanism is ideal for processing materials that tend to clog or stick during other crushing methods. With its robust design and ability to handle a wide range of materials, the Chain Mill is particularly useful in industries like agriculture, mining, and waste management.

Key Features and Advantages

-

High Efficiency and Performance

SEDİROGLU İNTERNATİONAL The Chain Mill’s high-speed rotating chains provide rapid material breakdown, ensuring maximum efficiency. Its consistent performance helps maintain steady production rates, even in demanding environments. -

Low Maintenance and Durability

Built with durable steel components, SEDİROGLU İNTERNATİONAL Chain Mills are designed to withstand harsh operating conditions. The simple construction reduces wear and tear, keeping maintenance costs low while ensuring long-term reliability. -

Eco-Friendly Operation

Chain Mills are energy-efficient, consuming less power than many alternative crushing systems. This not only lowers operational costs but also reduces environmental impact, making it a sustainable choice for modern industries. -

Versatility Across Applications

Whether breaking down fertilizers, animal bedding, or sticky materials, the Chain Mill adapts to a variety of tasks. Its ability to handle diverse material types makes it a flexible solution for industries looking for reliable and adaptable machinery.

Applications of Chain Mills

- Fertilizer Production: Ideal for crushing raw materials into fine particles, ensuring even distribution and improved product quality.

- Chemical Processing: Efficiently processes sticky or viscous materials, improving overall manufacturing efficiency.

- Agricultural Waste Management: Breaks down organic waste for easier composting or repurposing, contributing to sustainable practices.

- Mining and Quarrying: Processes materials into desired sizes, reducing waste and enhancing resource utilization.

Why Choose a Chain Mill?

Investing in a Chain Mill ensures that your material processing needs are met with precision and efficiency. Its ability to handle challenging materials, combined with its eco-friendly and cost-effective design, makes it a top choice for businesses aiming to optimize their operations.

In conclusion, a Chain Mill is more than just a crushing machine—it’s a solution for modern industries seeking efficiency, sustainability, and reliability. Whether you’re in agriculture, mining, or manufacturing, this versatile equipment is the key to improving productivity while reducing costs.

Make the smart choice today by incorporating a Chain Mill into your operations, and experience the difference in material processing like never before!