- Sediroglu

- 02 February 2025

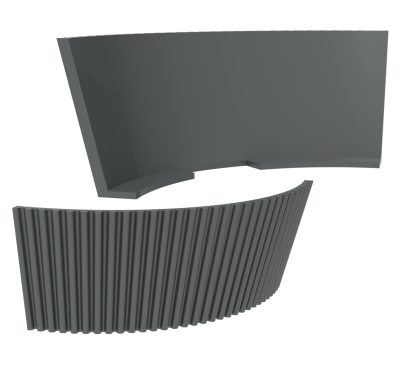

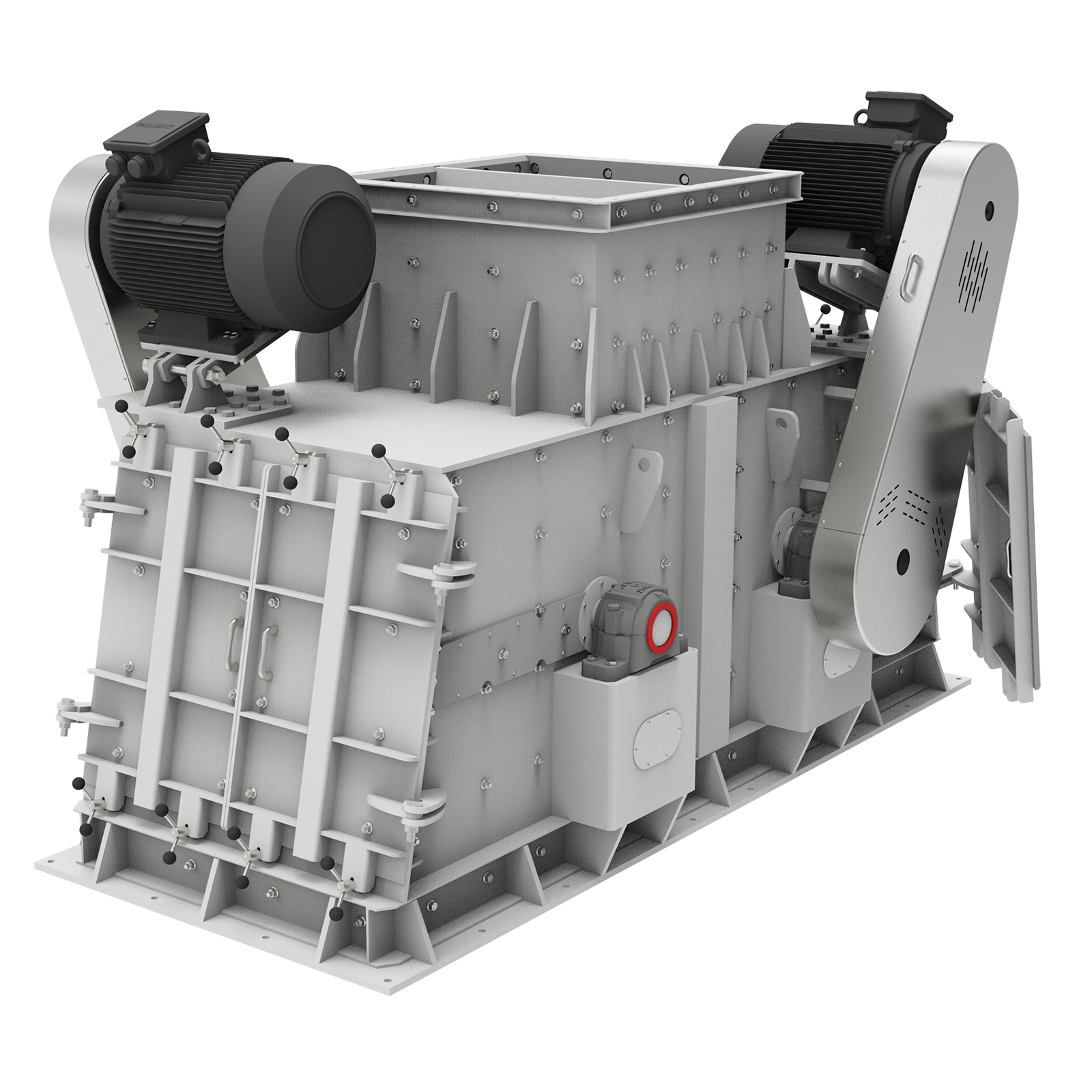

What chains should be used for the Chain Mill Crusher

Which Chains to Use for a Chain Mill Crusher: Quality and Characteristics

Chains are a key component in the operation of a Chain Mill Crusher, and their quality directly impacts the machine's performance and longevity. To ensure maximum efficiency and reduce maintenance costs, it is crucial to select the right chains based on operating conditions.

Chain Material

For a Chain Mill Crusher, it is recommended to use chains made of high-strength alloy steel. This material is resistant to wear and corrosion and has high tensile strength, ensuring durability in demanding conditions.

Hardening and Heat Treatment

Chains should undergo thermal processing to enhance their wear resistance. The degree of hardening is particularly important for protecting against mechanical damage when working with hard and abrasive materials.

Chain Size and Pitch

The size of the chains must match the specifications of the machine. Incorrect chain pitch can lead to uneven wear or even damage to the equipment, affecting overall performance.

Lubrication and Anti-Corrosion Coatings

Using lubricated or galvanized chains helps extend the equipment's lifespan, especially when operating in aggressive environments or high-humidity conditions.

Choosing the Right Chain for a Chain Mill Crusher

Selecting the right chain is not just about cost savings; it is also essential for ensuring uninterrupted machine operation. Consulting with manufacturers or chain suppliers is recommended to find the optimal solution for your specific needs.