- Sediroglu

- 20 December 2024

Filter Bag Cleaning

Enhancing Air Quality with Filter Bag Cleaning Machines in Industrial Facilities

In modern industrial facilities, maintaining optimal air quality is not just a regulatory requirement but also a critical factor for efficient production processes and worker health. The filter bag cleaning machine plays a pivotal role in ensuring that air filtration systems operate effectively, particularly in facilities where dust and particulate matter are generated in significant amounts. Sediroglu International, a leader in industrial machinery, offers state-of-the-art filter bag cleaning machines designed to improve air quality and enhance operational efficiency.

The Importance of Air Filtration in Industrial Facilities

Industrial environments, such as cement plants, chemical factories, and food processing facilities, are hotspots for airborne pollutants. Dust particles generated during production processes can lead to equipment malfunction, decreased productivity, and health risks for workers. Air filtration systems are the primary defense against these pollutants, capturing harmful particles and allowing clean air to circulate. At the heart of these systems are filter bags, which act as a barrier to trap dust and other particulates.

However, over time, the pores of these filter bags become clogged with accumulated dust, reducing their effectiveness. This is where the filter bag cleaning machine becomes essential. By restoring the filter bags to their original condition, these machines ensure that air filtration systems maintain their performance and efficiency.

How Does a Filter Bag Cleaning Machine Work?

The primary function of a filter bag cleaning machine is to remove dust and debris from used filter bags, thereby restoring their efficiency. The process involves several steps:

- Filter Bag Removal: Used filter bags are detached from the filtration system.

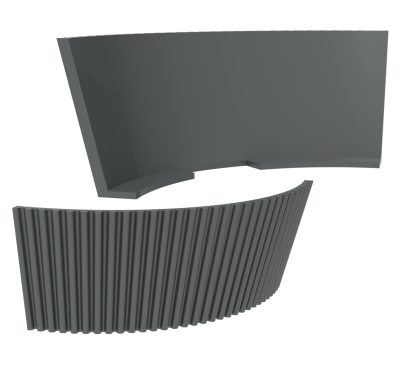

- Insertion into the Cleaning Machine: The bags are placed into the cleaning machine, which is equipped with advanced brushes and pneumatic systems.

- Dust Removal Process: The machine uses a combination of brushing and air jets to dislodge the dust particles embedded in the fabric of the bags.

- Inspection and Reuse: After cleaning, the bags are inspected for any damage and, if deemed suitable, are reinstalled in the filtration system.

This process not only ensures that the filtration system operates at peak efficiency but also reduces the frequency of replacing filter bags, leading to significant cost savings.

Applications of Filter Bag Cleaning Machines

Filter bag cleaning machines are versatile and can be used across various industries, including:

- Cement Plants: To clean filter bags used in dust collectors, ensuring the capture of fine cement particles.

- Chemical Plants: For the removal of hazardous dust generated during chemical processing.

- Food Processing Facilities: To maintain high hygiene standards by eliminating flour and sugar dust.

- Metalworking: For cleaning filter bags that trap metal shavings and dust particles.

- Power Plants: To handle the ash and fine particulates produced during energy generation.

Advantages of Using Filter Bag Cleaning Machines

The benefits of integrating a filter bag cleaning machine into an industrial facility are numerous:

- Enhanced Filtration Efficiency: Regular cleaning ensures that filter bags operate at maximum capacity, effectively trapping airborne particles.

- Cost Savings: By extending the lifespan of filter bags, facilities can reduce their expenditure on replacements.

- Improved Air Quality: Cleaner filter bags mean better air filtration, leading to a healthier working environment.

- Sustainability: Reusing filter bags after cleaning reduces waste, making the process eco-friendly.

- Compliance with Regulations: Many industries are subject to strict air quality standards, and clean filter bags help facilities stay compliant.

Sediroglu International: A Trusted Name in Filter Bag Cleaning Technology

Sediroglu International is renowned for its innovative solutions in industrial air filtration. Their filter bag cleaning machines are designed with cutting-edge technology to meet the needs of modern industries. Features of Sediroglu International’s machines include:

- High-Performance Brushes: Capable of removing even the most stubborn dust particles.

- Pneumatic Cleaning Systems: For efficient dust removal without damaging the filter bags.

- User-Friendly Design: Easy-to-operate controls and ergonomic design make the machines suitable for all operators.

- Durability: Built with high-quality materials to withstand heavy-duty use.

- Customizable Options: Tailored solutions to meet the specific requirements of different industries.

Why Choose a Filter Bag Cleaning Machine?

As industries strive to adopt more sustainable practices, the importance of maintaining efficient air filtration systems cannot be overstated. Filter bag cleaning machines not only contribute to better air quality but also align with the goals of reducing waste and optimizing resource use. Facilities that invest in these machines can expect:

- Reduced Operational Downtime: Efficient cleaning minimizes disruptions caused by clogged filters.

- Better Worker Productivity: Cleaner air results in healthier workers, reducing absenteeism and increasing output.

- Enhanced Equipment Longevity: By preventing dust accumulation, other machinery in the facility experiences less wear and tear.

Future Trends in Filter Bag Cleaning Technology

The field of industrial air filtration is constantly evolving, with advancements aimed at improving efficiency and sustainability. Some emerging trends include:

- Automated Systems: Fully automated filter bag cleaning machines that require minimal human intervention.

- Smart Monitoring: Integration with IoT devices to monitor the condition of filter bags in real time.

- Energy Efficiency: Development of machines that consume less energy during the cleaning process.

Conclusion

In conclusion, filter bag cleaning machines are indispensable for maintaining air quality and operational efficiency in industrial facilities. Sediroglu International’s cutting-edge technology and commitment to quality make their machines a top choice for industries worldwide. By investing in these machines, facilities can ensure compliance with environmental regulations, reduce costs, and contribute to a healthier working environment.

Whether it’s in cement plants, chemical factories, or food processing facilities, the role of filter bag cleaning machines in ensuring clean air and efficient operations is undeniable. Sediroglu International continues to lead the way in providing reliable and innovative solutions for industrial air filtration needs.