- Sediroglu

- 17 December 2024

Filter Bag Cleaning Machine

Filter Bag Cleaning Machine are essential tools in flour mills and other industrial facilities, designed to optimize the performance of pneumatic and dust filter systems by effectively cleaning the filter bags. Over time, the filter bags in these systems can become clogged with fine particles, reducing their efficiency and potentially causing operational disruptions. Sediroglu International offers state-of-the-art Filter Bag Cleaning Machine that address this challenge, ensuring continuous and efficient performance.

In flour mills, the production process generates significant amounts of dust, particularly during grain grinding and sieving. This dust can accumulate in the air and on machinery, posing health risks to workers and affecting the overall hygiene and quality of the production environment. To combat these issues, pneumatic systems with bag filters are employed to capture airborne particles and maintain clean air within the facility. However, without proper maintenance, the filter bags in these systems can lose their effectiveness, leading to reduced air quality and increased operational costs.

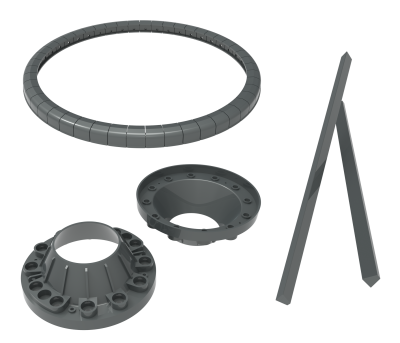

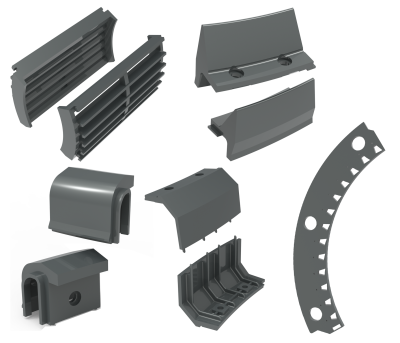

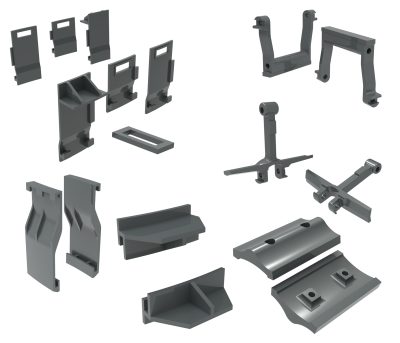

Sediroglu International’s Filter Bag Cleaning Machine are specifically engineered to restore the performance of these filter bags by thoroughly removing accumulated dust and debris. The machines use advanced brushing and air-suction mechanisms to clean the fine pores of the filter material, ensuring optimal airflow and dust-capturing efficiency. This process not only extends the life of the filter bags but also enhances the overall performance of the filtration system, leading to more efficient dust removal and better air quality in the facility.

One of the primary benefits of these cleaning machines is their ability to reduce the frequency of filter bag replacements. Regular cleaning with these machines helps maintain the integrity and functionality of the filter bags, saving costs associated with purchasing new filters and minimizing downtime for replacement. This cost-effective solution is especially valuable for large-scale operations, where even minor inefficiencies can result in significant financial losses over time.

In addition to cost savings, Sediroglu International’s Filter Bag Cleaning Machine contribute to a safer and more environmentally responsible operation. By ensuring that filter systems operate at peak efficiency, these machines help facilities comply with stringent environmental and safety regulations related to dust control. This compliance not only protects the health of workers but also supports the company's commitment to sustainable and eco-friendly practices.

The cleaning machines are designed for ease of use, with intuitive controls and compact designs that integrate seamlessly into existing workflows. Their robust construction ensures durability and reliable performance even in demanding industrial environments. Whether dealing with fine flour particles in mills or other types of dust in different industries, these machines provide consistent results, improving operational efficiency and maintaining a cleaner workspace.

Moreover, Sediroglu International’s Filter Bag Cleaning Machine are versatile and can be used across various industries beyond flour mills. From cement plants and chemical factories to woodworking and metal processing facilities, these machines deliver outstanding performance wherever dust control is critical. Their adaptability and high-quality construction make them an invaluable asset for any industry requiring effective filter maintenance.

In conclusion, Sediroglu International’s Filter Bag Cleaning Machine are essential for industries aiming to achieve superior dust management and maintain efficient operations. By keeping filter bags clean and fully functional, these machines enhance the performance of pneumatic and dust filtration systems, reduce maintenance costs, and promote a safer, healthier working environment. With a focus on innovation and quality, Sediroglu International continues to lead the way in delivering cutting-edge solutions for industrial dust control needs.