- Sediroglu

- 18 January 2025

How Jet Pulse Bag House Filters Improve Sustainability in Zinc Production Plants

How Jet Pulse Bag House Filters Improve Sustainability in Zinc Production Plants

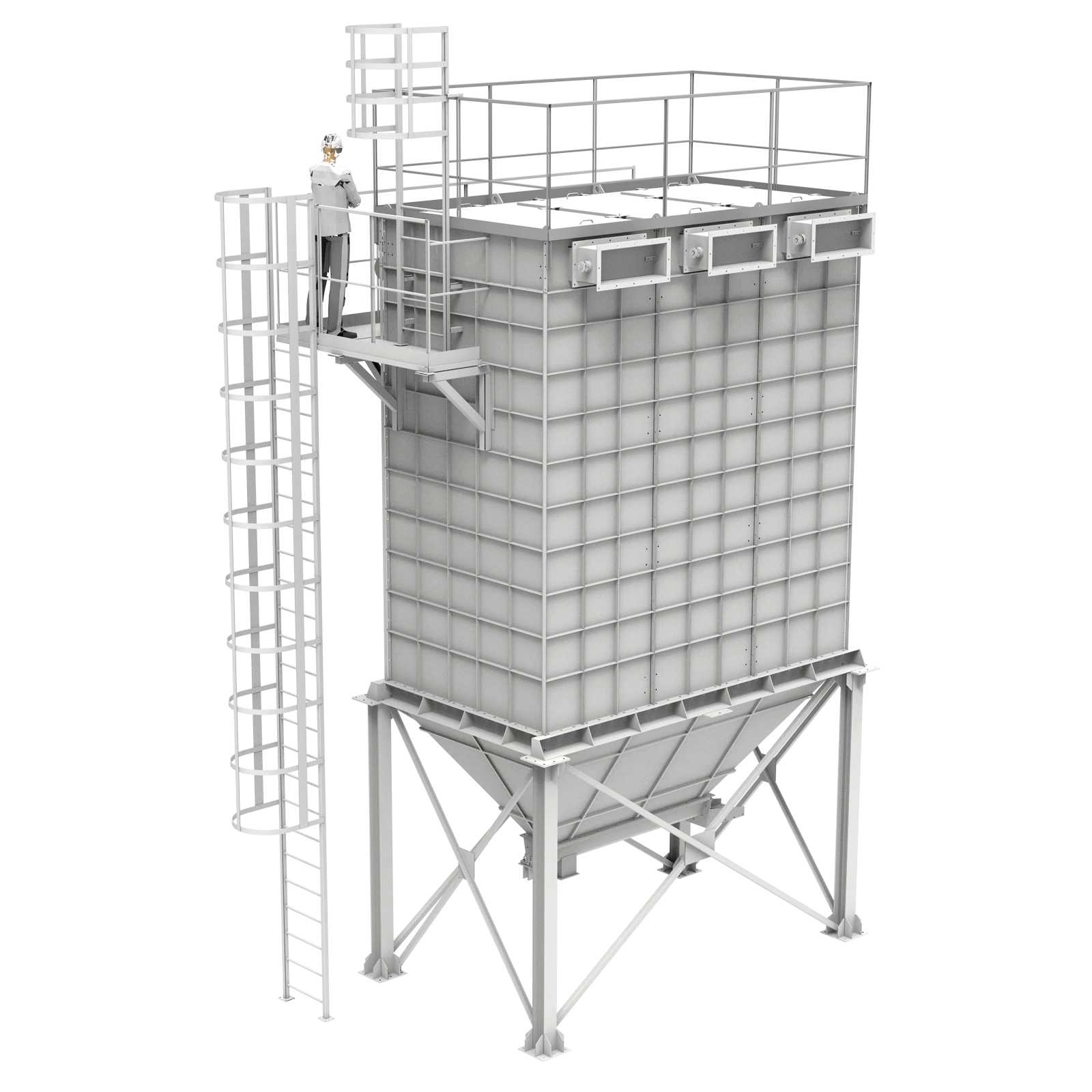

In today's industrial landscape, sustainability is no longer just an option but a necessity. Zinc production facilities are increasingly focusing on reducing their environmental footprint, and one of the most effective ways to achieve this is through the installation of Jet Pulse Bag House Filters. These advanced filtration systems not only improve air quality by capturing harmful dust emissions but also contribute to better energy efficiency, making them an essential solution for zinc producers committed to sustainability. Sediroğlu International provides state-of-the-art filtration solutions designed to enhance both environmental compliance and operational efficiency.

Efficient Dust Control for Cleaner Air

The primary function of Jet Pulse Bag House Filters is to capture dust and particulate matter generated during the zinc production process. This high-efficiency filtration system significantly reduces airborne pollutants, ensuring that the workplace remains safe and the surrounding environment stays protected. By capturing harmful dust particles, these filters help facilities comply with stringent environmental regulations, contributing to cleaner air both inside and outside the production plant.

Reducing Maintenance Costs and Improving Performance

One of the key advantages of the Jet Pulse Bag House Filter is its advanced pulse jet cleaning mechanism. This feature allows for continuous high performance without frequent maintenance, ensuring that the system runs efficiently over long periods. At Sediroğlu International, we understand that minimizing downtime is crucial for operational success. Therefore, our filters are designed to offer durability and reliability, reducing maintenance costs and improving the overall performance of zinc production facilities.

Supporting Energy Efficiency and Sustainability

In addition to reducing dust emissions, Jet Pulse Bag House Filters contribute to the energy efficiency of the entire zinc production process. These filtration systems are designed to consume minimal energy, helping to lower the carbon footprint of production plants. By reducing energy consumption, facilities not only reduce their environmental impact but also cut down on energy costs, making the entire operation more sustainable and cost-effective.

A Step Toward a Greener Future

The adoption of Jet Pulse Bag House Filters is a crucial step for zinc production facilities looking to embrace more sustainable practices. Investing in this technology ensures compliance with environmental standards while creating a cleaner, safer work environment. At Sediroğlu International, we are committed to providing cutting-edge solutions that improve sustainability in the zinc industry, offering high-efficiency filtration systems that help reduce costs, improve air quality, and protect the environment for years to come.