- Sediroglu

- 13 November 2024

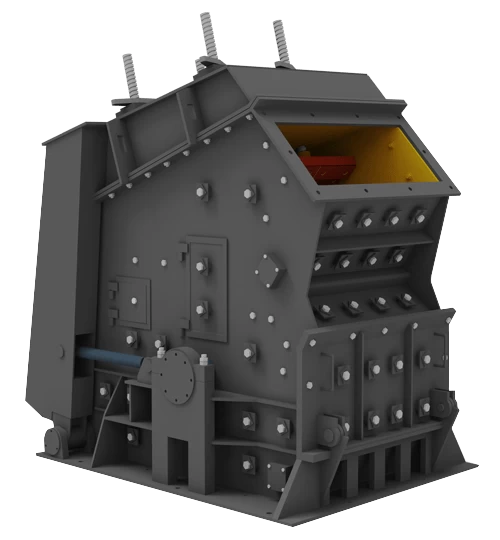

Primary Impact Crushers

The working principle of a Primary Impact Crusher involves processing materials using impact force rather than pressure.

Materials are fed into the crusher, where they come into contact with rotating hammers or blow bars. The force generated by the rotation causes the materials to collide with each other and with breaker plates inside the machine, fracturing them into smaller pieces.

Here is a detailed overview of how this process works and how SEDIROGLU INTERNATIONAL designs their impact crushers for maximum efficiency:

Material Feeding: Materials are introduced into the crushing chamber through a large feed opening, which allows even larger materials to be processed without jamming.

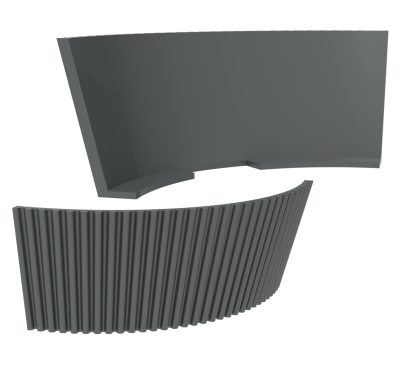

Impact Crushing: Once inside, the high-speed rotation of blow bars or hammers forces the materials to hit against fixed plates. This impact breaks down the materials into smaller, more uniform pieces, which is ideal for creating finely crushed products.

Secondary Impacts: After the initial impact, particles that are not crushed to the desired size may be subjected to secondary impacts as they rebound off breaker plates. This ensures consistent particle size and shape.

Material Discharge: Finally, crushed materials are discharged from the bottom of the machine, and they can be further processed or used as is, depending on the application.

SEDIROGLU INTERNATIONAL manufactures primary impact crushers with durability and efficiency in mind, utilizing wear-resistant materials and optimized designs to handle high-capacity loads. These crushers are also designed for ease of maintenance, with quick access to wear parts, reducing downtime and operational costs.

In summary, SEDIROGLU INTERNATIONAL's Primary Impact Crushers combine efficient impact force with robust construction to provide a reliable solution for primary crushing in mining, aggregates, and recycling applications. This innovative design ensures higher productivity and consistent quality in material processing.