- Sediroglu

- 06 November 2025

Why Precision Casting Matters in Cement Equipment Manufacturing

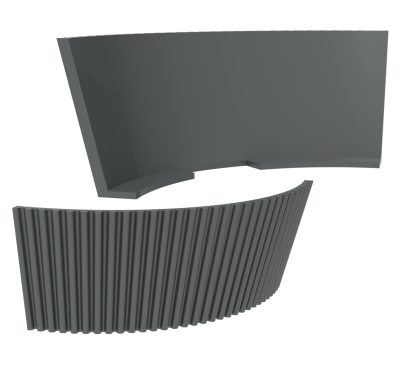

Precision casting is a critical process in producing durable cement plant equipment. High-quality casting ensures parts such as gears, housings, and valves fit perfectly, withstand extreme conditions, and extend machinery lifespan.

At Sediroglu International, we specialize in precision casting for all cement equipment components. Using advanced techniques and premium materials, we provide parts that meet exact specifications and operational demands.

Reliable cast parts reduce unplanned downtime, enhance production consistency, and maintain safety standards. Choosing precision-engineered components from Sediroglu International guarantees that your cement plant operates smoothly and efficiently.

Energy efficiency is a key factor in modern cement production. Worn or low-quality spare parts can increase energy consumption and reduce plant performance. Sediroglu International supplies high-quality replacement parts designed for optimal performance and durability.

Using reliable parts for cyclones, conveyors, and aspirators minimizes mechanical resistance, reduces downtime, and supports sustainable operations. Investing in precision-engineered components ensures smoother operation, lower energy bills, and longer equipment lifespan.

Cement plants that prioritize high-quality spare parts experience increased productivity, lower costs, and improved sustainability. Partner with Sediroglu International to maintain energy-efficient and reliable operations.