- Sediroglu

- 05 November 2025

The Importance of High-Quality Spare Parts in Cement Plant Maintenance

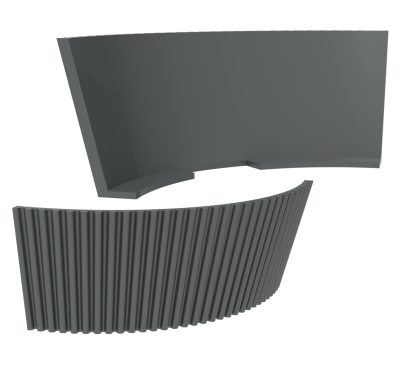

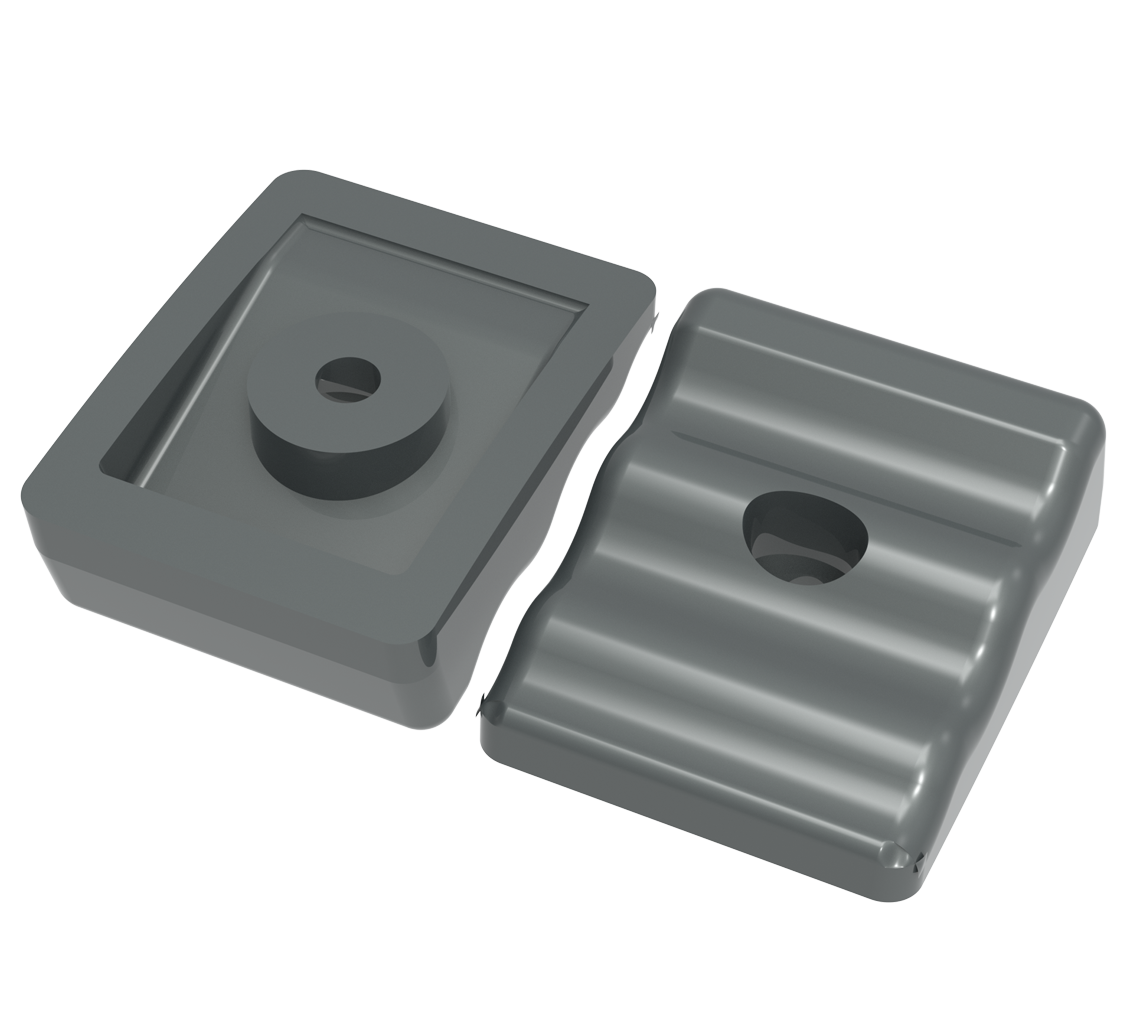

Cement plants rely on durable machinery that operates under extreme conditions, including high temperatures, abrasive materials, and continuous mechanical stress. Using high-quality spare parts is essential to ensure uninterrupted production, reduce costly downtimes, and maintain the overall efficiency of the facility. At Sediroglu International, we specialize in casting, manufacturing, and supplying replacement parts for all critical cement plant equipment — including cyclones, aspirators, screw conveyors, kiln components, crusher jaws, hammer heads, and other vital machinery parts.

Our precision-engineered spare parts are designed to withstand the harsh operating conditions typical of cement plants. By employing advanced casting techniques, careful material selection, and rigorous quality control, Sediroglu International ensures that each part delivers optimal strength, wear resistance, and dimensional accuracy. This guarantees a long service life, precise fit, and seamless compatibility with leading cement plant systems.

Regular maintenance and timely replacement of wear parts are crucial for maximizing operational efficiency. Components such as screw conveyors and kiln linings are subject to continuous abrasion, while crusher jaws and hammer heads endure repeated impact forces. Using substandard or worn parts can lead to misalignments, excessive vibration, unplanned shutdowns, and even damage to adjacent equipment. By providing high-quality, durable replacement parts, Sediroglu International helps plants prevent these costly issues and maintain smooth, continuous operations.

In addition to mechanical performance, our spare parts are designed to enhance energy efficiency. Properly fitted and correctly functioning components reduce unnecessary friction, minimize energy loss, and improve the overall efficiency of the plant. This not only lowers operating costs but also contributes to a more sustainable production process.

Choosing Sediroglu International as a partner also means benefiting from our expertise in material science and engineering. Our engineers analyze the specific operating conditions of each plant — including temperature ranges, particle sizes, chemical exposure, and mechanical stresses — to recommend the most suitable materials and designs for each component. This proactive approach ensures that replacement parts not only meet but often exceed the performance requirements of modern cement production.

Ultimately, investing in high-quality spare parts from Sediroglu International enables cement producers to reduce maintenance costs, improve plant safety, ensure continuous production, and extend the service life of critical equipment. With our commitment to precision, durability, and operational reliability, Sediroglu International remains the trusted partner for cement industry solutions worldwide.