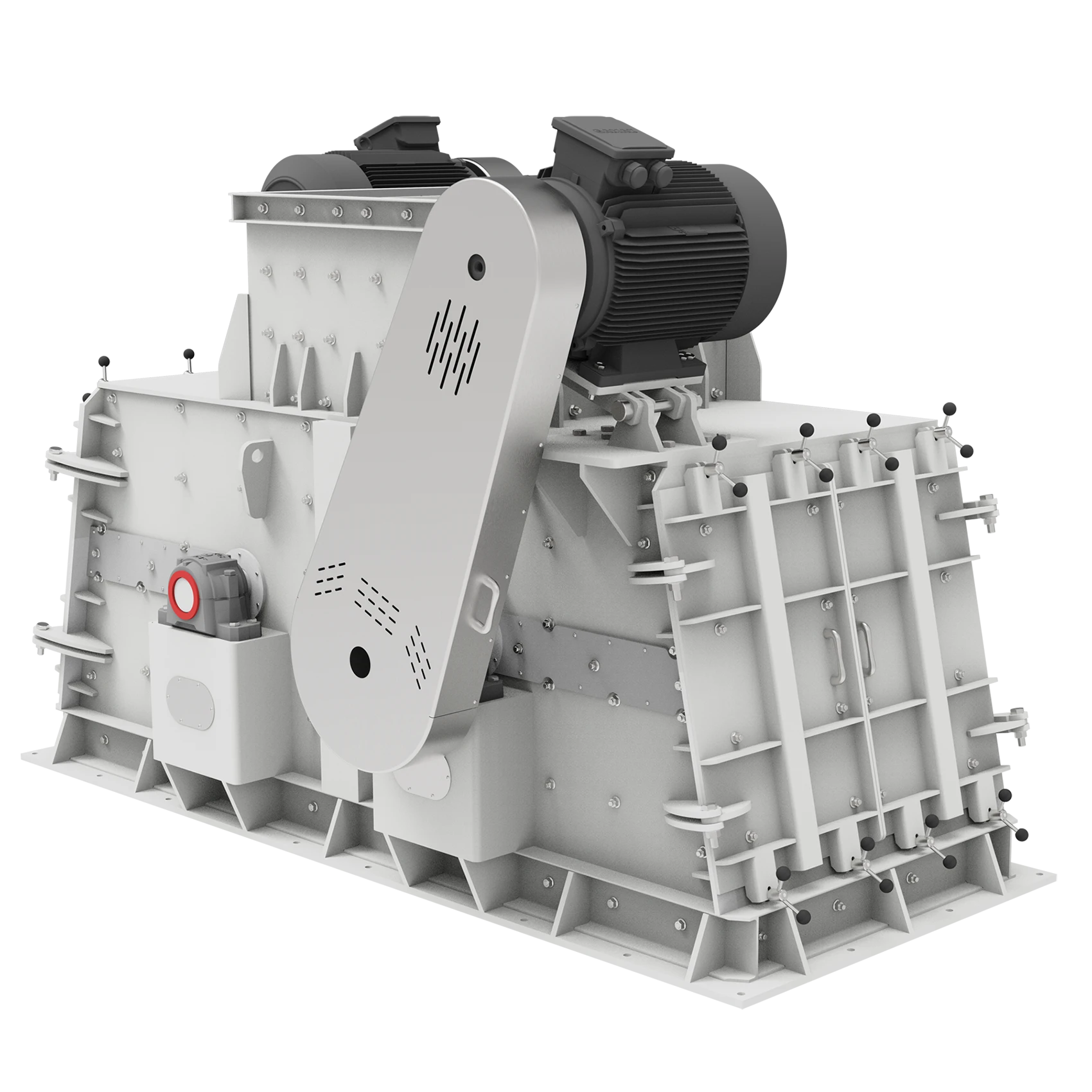

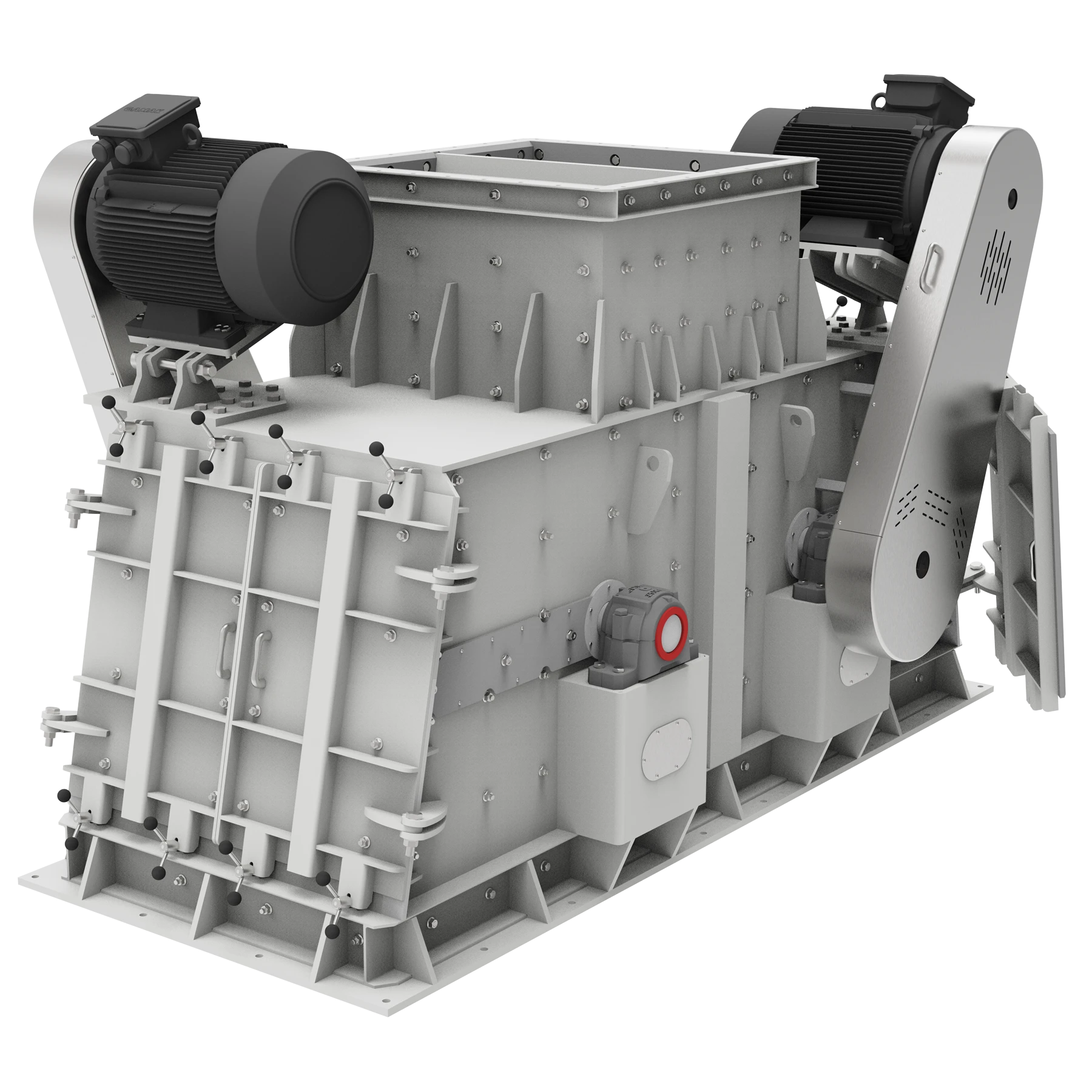

Sediroglu Chain Mill Crushers: Precision Crushing for Diverse Applications

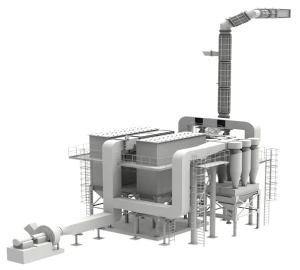

Working Principle

Chain Mill Crushers operate by using high-speed rotating chains to pulverize materials into smaller, uniform sizes, ensuring efficient processing for industries like fertilizer, mining, and recycling. This robust design minimizes maintenance and maximizes performance, making it a cost-effective solution for breaking down clumped or coarse materials with precision and reliability.

Durable and Efficient Chain Mill Crushers for Cement and Feed Mills

Technical Specifications

Chain Mill Crushers are engineered with a robust chain-driven mechanism, designed to pulverize materials into uniform sizes for optimal processing in industries like fertilizer, mining, and recycling. Featuring adjustable chain speeds, replaceable wear parts, and durable construction, these machines ensure long-lasting performance with minimal maintenance. Their compact design supports easy installation in various setups, while their energy-efficient operation reduces costs. Ideal for breaking down clumped or coarse materials, Chain Mill Crushers provide reliable, cost-effective, and sustainable solutions for diverse industrial applications.

Chain Mill Crushers by Sediroglu: Energy-Efficient Crushing Solutions

Application Areas

Chain Mill Crushers offer numerous advantages, including efficient material reduction for industries such as fertilizer, mining, and recycling. Their simple yet robust design ensures low maintenance and high durability, reducing downtime and operational costs. With adjustable chain speeds and replaceable wear parts, they provide flexibility to handle various materials and adapt to different industrial needs. These crushers deliver consistent particle sizes, enhancing downstream processes and overall productivity. Energy-efficient and compact, Chain Mill Crushers are ideal for space-limited installations, making them a sustainable and cost-effective solution for diverse industrial operations.

Chain Mill Applications and Benefits by Sediroglu International

At Sediroglu International, we pride ourselves on offering high-quality machinery solutions for various industries, and our Chain Mill is a testament to this commitment. Chain Mill Crushers are used in fertilizer production facilities.

The Chain Mill is a versatile and robust crushing machine designed to break down materials into smaller, more manageable pieces. Its unique chain-driven mechanism ensures efficiency and adaptability, making it an indispensable tool in several sectors. Below, we detail the many applications and benefits of the Chain Mill, demonstrating why it is the ideal choice for your operational needs.

What is a Chain Mill?

A Chain Mill is a type of crusher that utilizes a rotating chain mechanism to pulverize materials. Chain Mill Crushers are used in cement factories The chains swing at high speeds, striking the material repeatedly until it breaks down into smaller particles. This design is particularly effective for reducing friable and moderately hard materials, ensuring consistency in particle size and quality.

Applications of Chain Mills

1. Fertilizer Production

One of the primary applications of the Chain Mill is in the production of fertilizers. Chain Mill Crushers are used in recycling facilities This machine is specifically designed to crush clumps of material and ensure that fertilizers remain free-flowing and easy to distribute. Whether it’s organic or chemical fertilizers, the Chain Mill efficiently handles:

-

Breaking down hardened lumps.

-

Pulverizing raw materials such as phosphate rock or limestone.

-

Ensuring uniform particle size for better soil absorption.

2. Mining and Mineral Processing

In mining operations, the Chain Mill is used for reducing the size of soft to medium-hard minerals. Its reliable performance makes it a popular choice for:

-

Crushing ores before further processing.

-

Breaking down minerals like gypsum, clay, and limestone.

-

Preparing raw materials for separation or chemical treatment.

3. Chain Mill Construction Industry

The construction sector benefits significantly from the Chain Mill’s ability to crush materials like gravel, crushed stone, and other aggregates. These materials are essential for:

-

Road construction and maintenance.

-

Producing cement and concrete.

-

Landscaping projects that require specific granular sizes.

4. Chain Mill Recycling Operations

The recycling industry has found immense value in Chain Mills, as they effectively reduce waste materials into reusable forms. Applications include:

-

Crushing glass into sand-like particles.

-

Breaking down plastics for reprocessing.

-

Reducing metal scraps and lightweight composites.

5 .Chain Mill Chemical Industry

Chain Mills play a pivotal role in the chemical industry, where precise particle size is critical. They are used for:

-

Preparing materials for chemical reactions.

-

Granulating materials for consistent mixing.

-

Pulverizing raw ingredients in pharmaceuticals or industrial chemicals.

6. Chain Mill Agriculture

Farmers and agricultural industries use Chain Mills to prepare various products, including animal feed and soil conditioners. Common uses include:

-

Crushing dried manure or compost for fertilizer.

-

Breaking down grains or feed materials for livestock.

-

Pulverizing soil additives for improved farming efficiency.

-

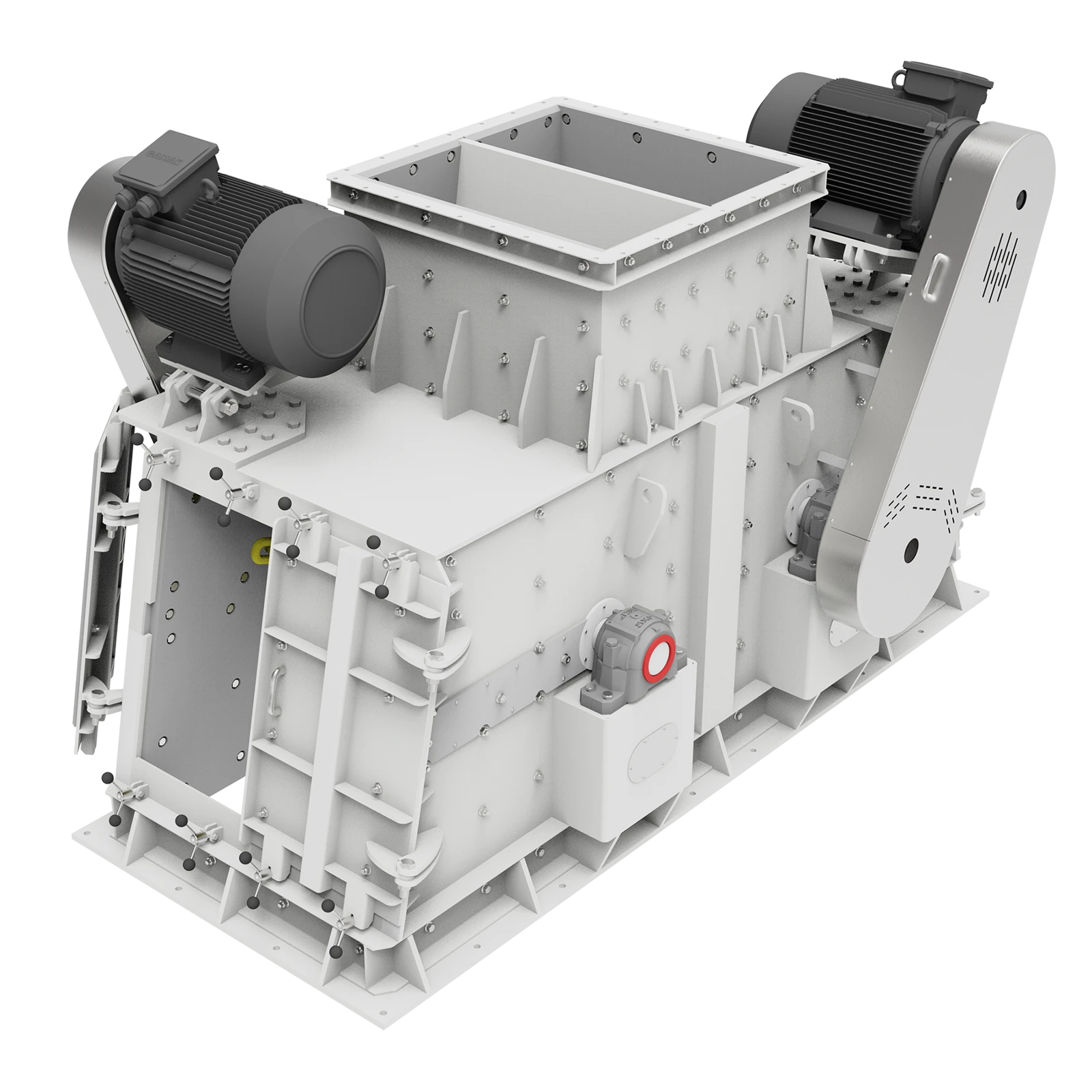

Advantages of Using Chain Mills from Sediroglu International

Chain Mill Efficiency

Chain Mills deliver high-speed crushing performance, ensuring materials are processed quickly and efficiently. This reduces downtime and increases throughput, making it ideal for high-volume operations.

Chain Mill Versatility

Whether you’re processing fertilizers, minerals, or recyclable materials, the Chain Mill adapts seamlessly to various requirements. Its ability to handle diverse materials makes it a cost-effective investment.

Chain Mill Consistency

Uniform particle size is critical in many industries. The Chain Mill’s design ensures that materials are pulverized evenly, resulting in consistent quality and performance in downstream processes.

Chain Mill Low Maintenance

The Chain Mill’s simple design reduces the risk of mechanical failure. At Sediroglu International, we build our machines with durable materials, ensuring minimal maintenance and long service life.

Chain Mill Cost-Effectiveness

Compared to other crushing machines, the Chain Mill is highly economical. It offers high performance at a relatively low operational cost, making it an excellent choice for businesses of all sizes.

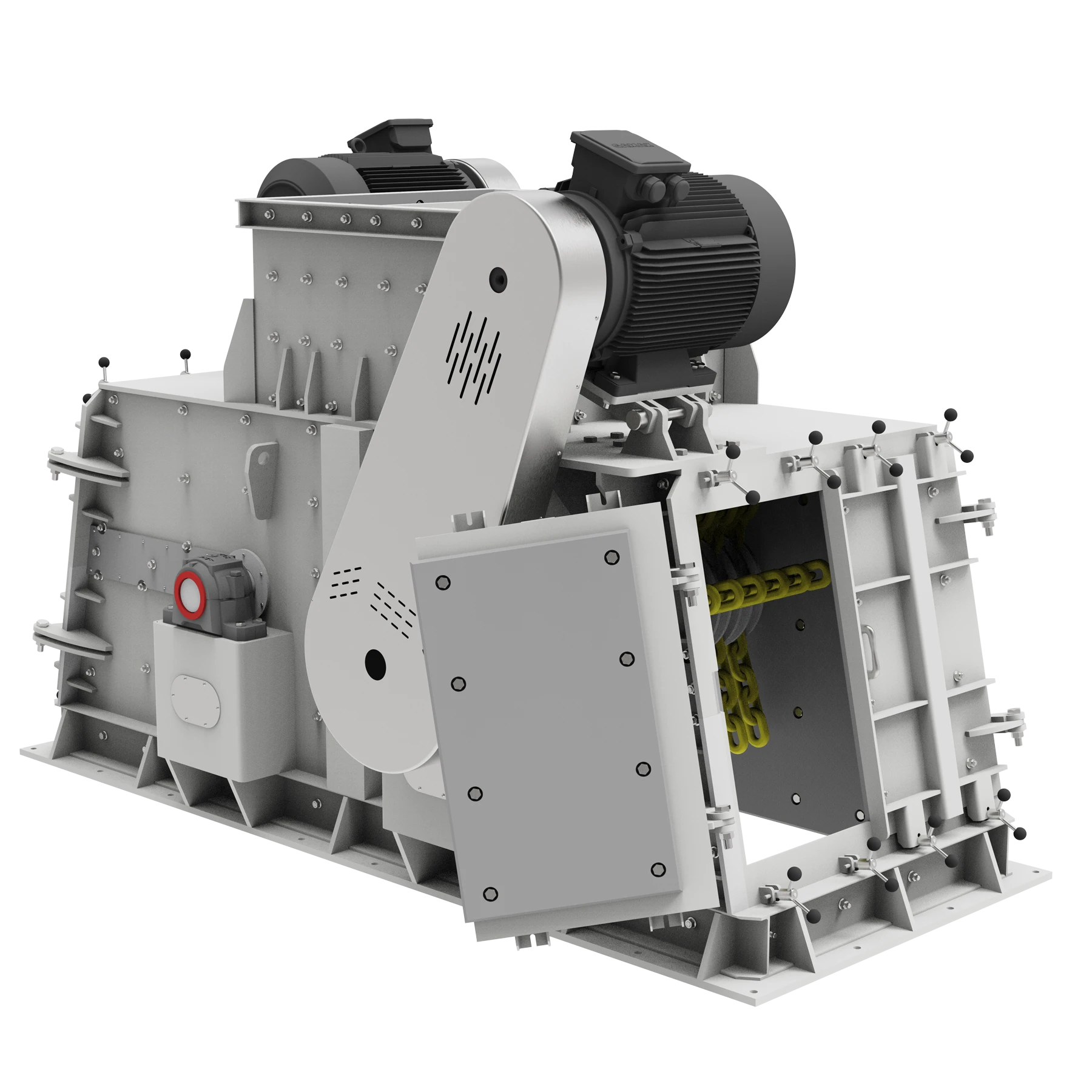

How Chain Mills Work

The Chain Mill operates on a straightforward principle. Chain Mill Crushers are used in mining facilities Material is fed into the crusher, where high-speed rotating chains strike and break it down. The crushed material exits through a grate or screen, ensuring that only appropriately sized particles move forward. This simple yet effective mechanism ensures reliability and efficiency.

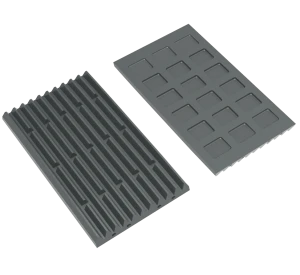

Customizable Features

At Sediroglu International, we understand that every operation has unique requirements. That’s why our Chain Mills come with customizable features, including:

-

Adjustable chain speeds to control particle size.

-

Replaceable wear parts to extend the machine’s lifespan.

-

Variable feed hoppers for different material types.

-

Environmental Benefits

Using a Chain Mill contributes to sustainability in several ways:

-

Chain Mill Reduced Waste: By breaking down materials into reusable sizes, it minimizes waste sent to landfills.

-

Chain Mill Energy Efficiency: Our Chain Mills are designed to consume less energy while maintaining high performance.

-

Chain Mill Recyclable Materials: They play a crucial role in converting waste into valuable products, supporting a circular economy.

-

Industries that Trust Sediroglu International Chain Mills

Businesses across the globe rely on our Chain Mills for their operations. Some industries that commonly use our machines include:

-

Agriculture and Farming: For fertilizer and feed preparation.

-

Mining: For ore and mineral processing.

-

Why Choose Sediroglu International?

When you choose Sediroglu International, you’re not just buying a machine; you’re investing in a partnership. Chain Mill Crushers are used in mineral processing facilities Our commitment to quality, innovation, and customer satisfaction sets us apart. Here’s why clients trust us:

-

Expertise: Decades of experience in industrial machinery.

-

Customization: Tailored solutions for unique operational needs.

-

Support: Comprehensive after-sales support and service.

-

Quality: Machines built with premium materials for durability and performance.

-

Conclusion

The Chain Mill from Sediroglu International is a versatile, efficient, and reliable crushing solution for a wide range of industries. Chain Mill Crushers are used in coal production facilities From fertilizer production to recycling, this machine delivers exceptional performance and adaptability. By investing in a Chain Mill, you ensure higher productivity, lower operational costs, and a positive environmental impact.

Contact Sediroglu International today to learn more about how our Chain Mills can enhance your operations and help you achieve your goals.

-

Construction: For aggregate and material production.

-

Recycling: For waste reduction and material reprocessing.

-

Chemicals: For precise material preparation.

×

![]()

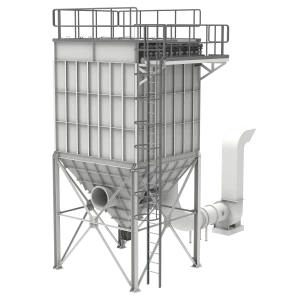

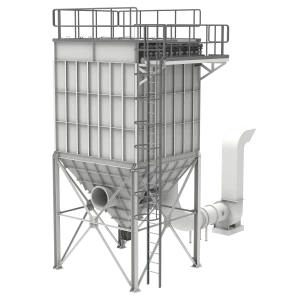

The industrial bag filter offered by Sediroglu International is designed to efficiently capture dust and particulate matter generated in furniture, textile, and wood processing plants. With advanced filtration technology, this fil...

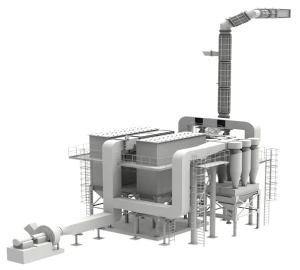

Sediroglu International’s industrial dust filters are designed for effective dust control in iron and steel, aluminum, and ore processing plants. Featuring high-capacity filtration technology, they improve air quality and provide...

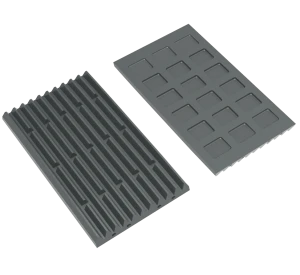

Sediroglu International supplies all essential jaw crusher spare parts, including premium fixed casting jaws, ensuring durability, compatibility, and long-lasting crusher performance in demanding applications.