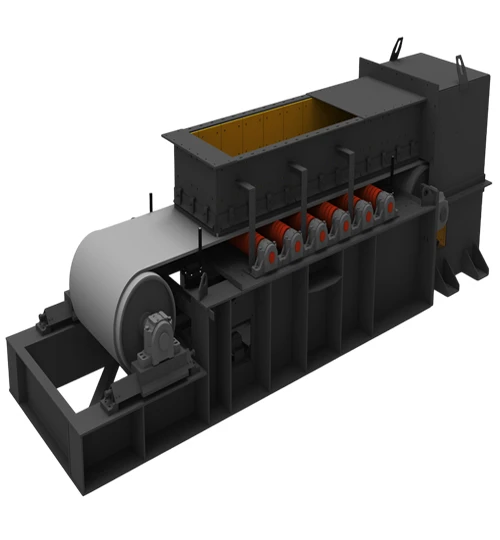

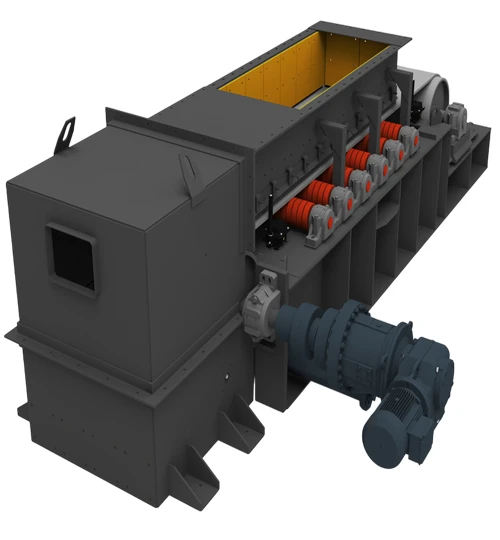

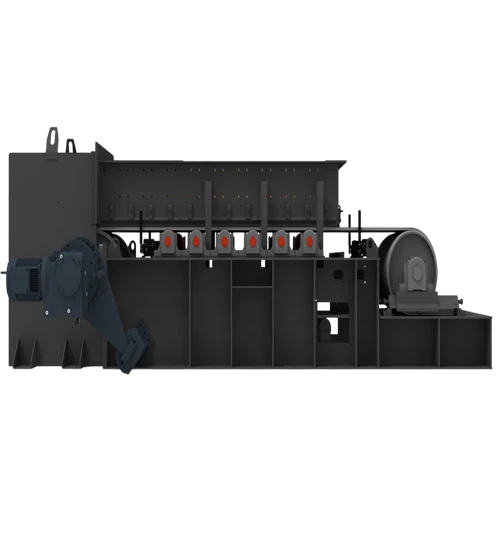

Sediroglu International’s belt feeders are designed to optimize material flow across a wide range of industrial processes, ensuring efficiency and reliability in material handling. These advanced feeders are engineered to withdraw materials, such as fines, wet substances, or aggregates, from hoppers, bins, or stockpiles and transport them smoothly to downstream equipment like crushers, screens, or conveyors. The precise control over feed rates provided by these feeders ensures that operations run continuously without delays, improving overall system performance.

The primary function of Sediroglu International’s belt feeders is to maintain a constant and uniform material flow, minimizing the risk of blockages or overloading in the system. This is achieved by integrating powerful motorized drive systems that control the belt speed, allowing for easy adjustments to meet varying operational requirements. The feeders are built with high-quality, wear-resistant materials, ensuring durability and longevity, even when handling abrasive or heavy-duty materials.

Sediroglu International’s belt feeders are equipped with advanced automation systems that allow real-time monitoring and adjustments, further enhancing their efficiency. These systems can automatically optimize feed rates based on material characteristics and operational needs, reducing manual intervention and improving productivity. Additionally, integrated sensors provide valuable data on material load, belt tension, and operational performance, ensuring smooth and uninterrupted operations.

Sediroglu International offers advanced belt feeder solutions designed to ensure continuous and efficient operations across various industrial sectors. These state-of-the-art feeders are built to handle a wide range of materials, including wet, fine, or abrasive substances, withdrawing them from hoppers, bins, or stockpiles and feeding them into downstream equipment such as crushers, screens, or conveyors. The core function of these feeders is to provide a consistent, uninterrupted flow of materials, which is critical for maintaining smooth and continuous processing in industries such as mining, construction, and recycling.

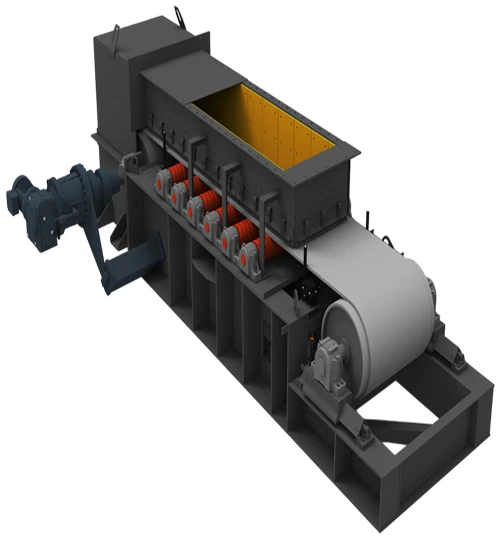

The belt feeders from Sediroglu International are engineered with precision to meet the demands of heavy-duty operations. They feature heavy-duty steel frames, durable wear-resistant belts, and powerful drive motors to ensure reliable performance even under harsh conditions. The machines are designed to handle large volumes of materials, delivering the required feed rate without compromising on speed or efficiency. Their robust construction makes them ideal for operations in challenging environments, including high-capacity mining and construction sites.

One of the key benefits of Sediroglu International’s advanced belt feeders is their automation capabilities. Integrated control systems allow for real-time monitoring of performance and automatic adjustments to feed rates, ensuring optimal material flow at all times. This minimizes manual intervention and reduces the likelihood of system overloads or material blockages. The automation also provides data feedback, which helps operators track performance, identify potential issues, and maintain consistent production levels.

These belt feeders are also highly customizable, allowing businesses to tailor the system to their specific needs. Whether it's adjusting the belt speed, selecting the right materials for the conveyor, or integrating additional sensors for monitoring, Sediroglu International’s solutions are flexible and adaptable. This customization ensures that the feeder system can handle different types of materials with precision, improving overall process efficiency and reducing the risk of downtime.

Energy efficiency is another standout feature of Sediroglu International’s belt feeders. These feeders are designed to consume less energy while maintaining high-performance levels. The ability to fine-tune the material feed rates not only ensures that operations run smoothly but also helps businesses save on energy costs, contributing to more sustainable and cost-effective operations.

Furthermore, the feeders are built with maintenance in mind. The design allows for easy access to critical components, reducing the time required for routine checks or repairs. This user-friendly design contributes to minimizing downtime, allowing for continuous, trouble-free operations. The long service life of Sediroglu International’s belt feeders ensures that businesses get the most out of their investment.

In industries like mining, construction, and recycling, where efficient and continuous material handling is crucial, Sediroglu International’s advanced belt feeders provide the reliability and precision needed to enhance overall productivity. These feeders optimize material flow, reduce operational costs, and ensure smooth, uninterrupted operations across various stages of material processing.

Sediroglu International's belt feeders provide precision feeding for crushers and screens, offering a reliable and efficient solution for industries that require consistent material handling. These advanced machines are designed to withdraw materials—such as fines, aggregates, ores, and other types of bulk materials—from hoppers, bins, or stockpiles, and deliver them at a controlled and continuous feed rate to crushers, screens, or other processing equipment. The primary goal of these belt feeders is to optimize material flow, improve operational efficiency, and minimize disruptions in material processing operations.

Belt feeders from Sediroglu International are engineered with precision to ensure a steady, controlled feed of materials. These feeders are equipped with durable, wear-resistant belts that can withstand harsh industrial conditions, making them ideal for applications in mining, construction, recycling, and other sectors. The advanced belt drive system allows for precise control over the belt speed, which can be adjusted to meet the specific requirements of each application. This means that Sediroglu International's belt feeders can handle a wide variety of materials—whether dry, wet, fine, or coarse—with consistent accuracy and efficiency.

One of the main advantages of these belt feeders is their ability to provide a continuous, uninterrupted material flow, which is crucial for maintaining optimal productivity in industries like mining and construction. With a Sediroglu International belt feeder, operators can efficiently transport materials such as ores, rocks, or aggregates from storage points to processing equipment, such as crushers or screens, at a rate that meets production demands. This continuous feed ensures that crushers and screens operate smoothly, without interruptions or delays, reducing downtime and maximizing throughput.

The belt feeders are equipped with intelligent control systems that allow for real-time monitoring and adjustments to the feed rate, ensuring that materials are delivered at the correct pace. This automation feature enables operators to fine-tune the feed rates according to specific requirements, preventing overloading or underfeeding of the equipment. For instance, if a surge or gap in material is detected, the belt feeders can automatically adjust to deliver the required amount of material at the proper speed, helping to optimize efficiency and accuracy throughout the production process. This automation not only saves valuable time and effort but also improves the overall reliability of material handling systems.

Sediroglu International’s belt feeders are designed to meet the high demands of modern industrial applications. These machines are built with rugged, high-quality materials to ensure maximum durability, even in challenging environments. Their robust construction helps reduce wear and tear, extending the life of the belt feeders while ensuring optimal performance throughout their service life. The feeders are also designed with safety in mind, featuring emergency stop systems, overload protection, and sealed edges to minimize spillage, ensuring a smooth and secure material transfer.

The versatility of Sediroglu International's belt feeders makes them suitable for a variety of applications. In mining, they are used to convey ores, rocks, fines, and other bulk materials from stockpiles or storage hoppers to crushers and screens. This consistent flow of materials helps keep crushers and screens running efficiently, reducing downtime and improving productivity. In construction, these belt feeders can handle aggregates, raw materials, or recycled materials to various processing stages, providing a continuous and uniform feed rate for equipment. Recycling facilities also rely on these belt feeders to transport diverse materials such as plastics, metals, or construction waste, aiding in the processing of materials for reuse or disposal.

Furthermore, Sediroglu International’s belt feeders contribute to improved energy efficiency, as they are designed to operate at lower power levels while still delivering the required performance levels. With intelligent control systems, operators can fine-tune the belt speed and feed rates, optimizing energy consumption without compromising material handling efficiency. This feature not only helps businesses save on operational costs but also supports environmental sustainability goals by minimizing energy use in industrial processes.

Sediroglu International’s belt feeders are specifically designed to handle challenging materials such as wet and fine substances, offering a reliable solution for industries that require precise material handling under difficult conditions. These feeders are engineered with advanced features to ensure the smooth, continuous flow of materials from hoppers, bins, or stockpiles to downstream equipment like crushers, screens, and conveyors. The high-performance design of these belt feeders guarantees optimal feed rates, even when dealing with wet or fine materials, which can otherwise present challenges such as clumping, clogging, or inconsistent flow.

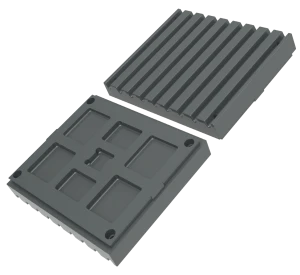

The belts used in Sediroglu International's feeders are made from durable, wear-resistant materials that can withstand the added stress of wet and fine materials without compromising performance. These specialized belts are designed to minimize spillage and prevent material buildup, ensuring a clean and efficient transfer. The feeders' powerful motorized drive system controls the speed and feed rate, providing precise material flow to prevent overloading or underfeeding of processing equipment, which is crucial when handling materials with varying moisture content or particle sizes.

Sediroglu International’s belt feeders are equipped with an intelligent control system that allows real-time monitoring and automatic adjustments to feed rates, helping to maintain consistent material flow. The automation features reduce the need for manual intervention and ensure that materials are fed accurately and continuously, which is particularly important when handling wet or fine materials that can be more difficult to manage. Additionally, sensors embedded within the system monitor key performance parameters, providing valuable data to operators for timely adjustments and maintenance.

These feeders are especially beneficial in industries such as mining, construction, and recycling, where materials often include wet or fine particles that require careful handling. In mining, for example, they help efficiently transport fine ores or slurry to crushers or screens, minimizing the risk of clogging or blockages. In construction and recycling, they are used to handle wet aggregates, waste, or recycled materials, ensuring smooth operation of processing equipment.

The robust construction of Sediroglu International’s belt feeders ensures long-lasting performance, even in harsh environments. They are built to reduce wear and tear while maintaining high efficiency, making them a reliable choice for demanding industrial operations. Their design also emphasizes energy efficiency, reducing power consumption while maintaining optimal performance levels, which helps lower operational costs over time.

In conclusion, Sediroglu International’s belt feeders provide an ideal solution for industries handling wet and fine materials. With their durable construction, intelligent automation, and precision control, these feeders ensure consistent and reliable material flow, even in the most challenging conditions. By optimizing material handling processes, these belt feeders help improve productivity, reduce downtime, and enhance overall system efficiency in a wide range of applications.