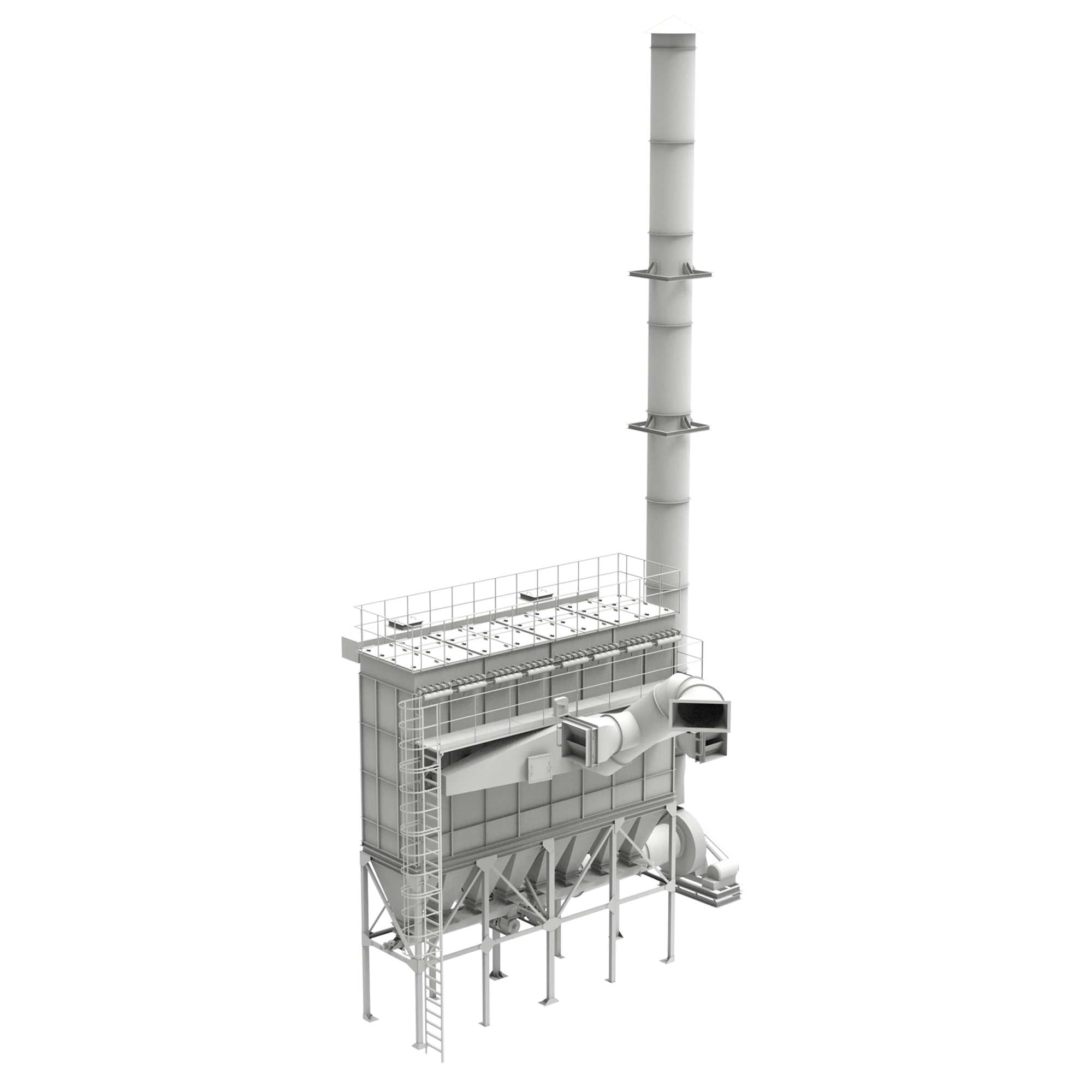

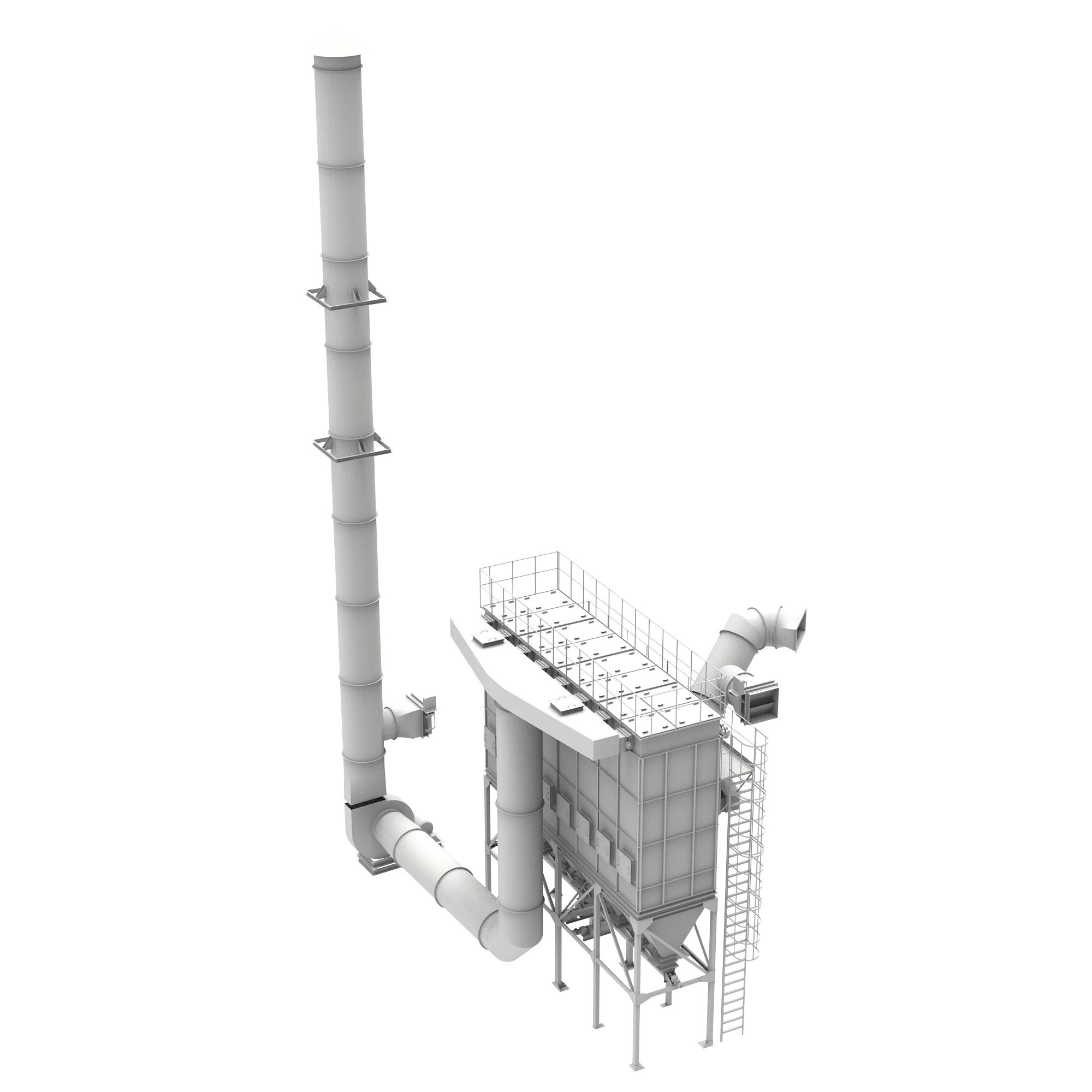

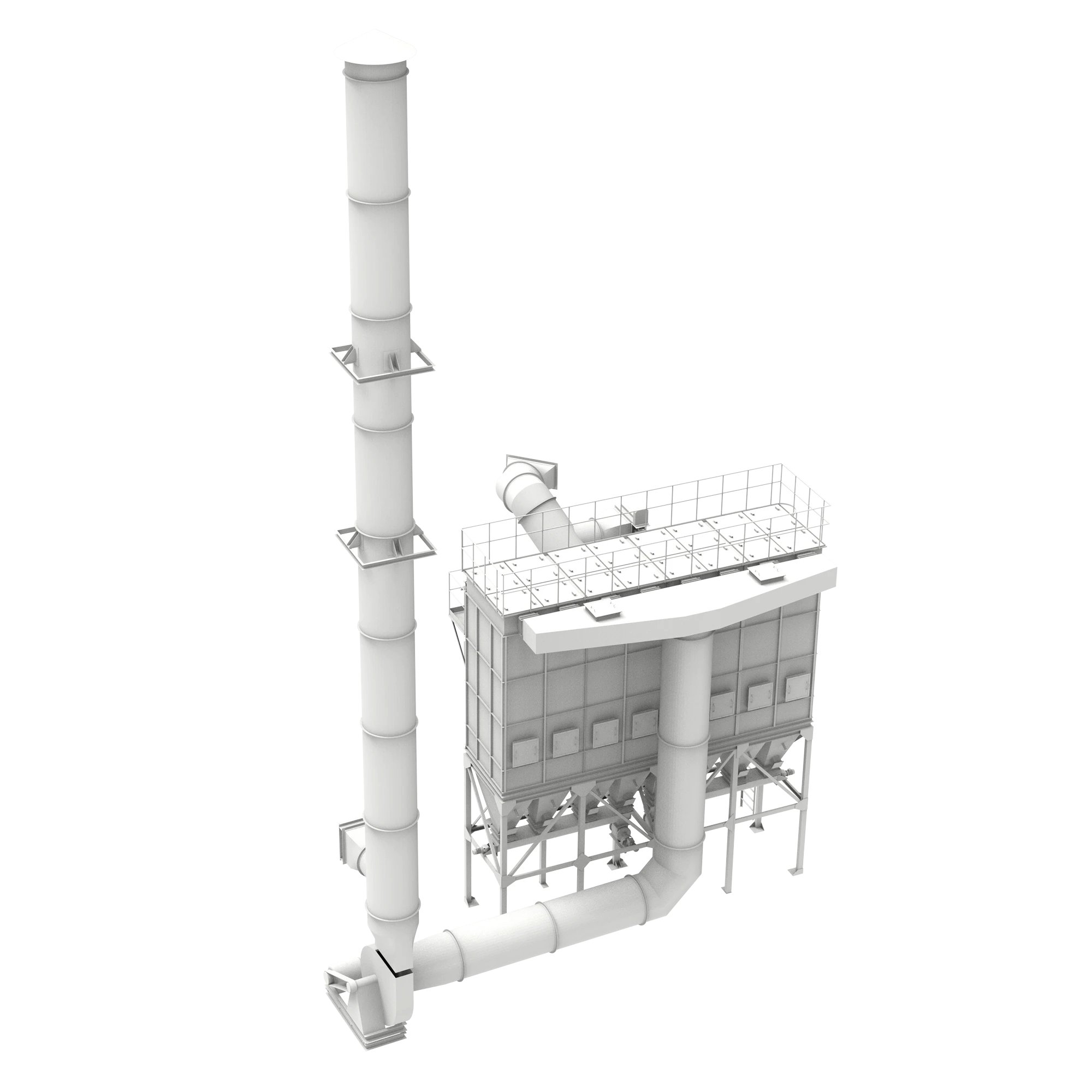

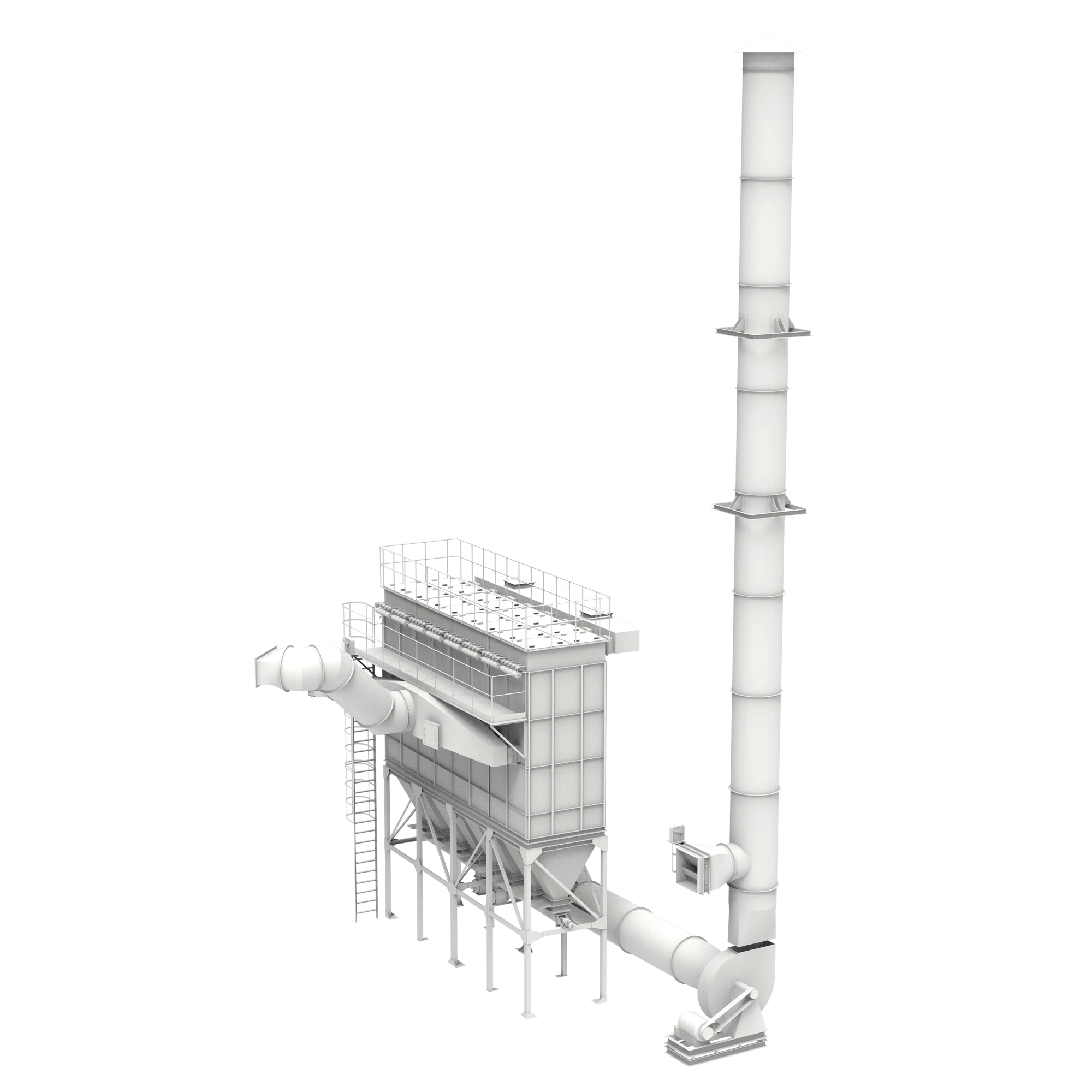

The Pulse Jet Bag Filter for Recycling Plants is a cutting-edge filtration solution designed to effectively manage dust and particulate emissions in recycling facilities. Recycling plants face various challenges, including managing airborne dust and maintaining a clean, safe working environment. Traditional filtration systems often struggle to meet these demands, leading to increased maintenance, downtime, and inefficiency. However, the Pulse Jet Bag Filter addresses these issues by offering superior filtration performance and advanced features that cater to the needs of modern recycling operations.

High-Efficiency Dust Collection

At the heart of the Pulse Jet Bag Filter’s design is its high-efficiency dust collection capability. Recycling plants generate a significant amount of dust during the sorting, shredding, and processing of materials. These airborne particles can pose serious health risks to workers, hinder the efficiency of machinery, and result in the facility failing to meet environmental standards. The Pulse Jet Bag Filter efficiently captures dust and particulate matter, ensuring cleaner air, improved air quality, and a healthier working environment for employees.

Pulse-Jet Cleaning Technology

One of the standout features of the Pulse Jet Bag Filter is its innovative pulse-jet cleaning mechanism. This technology works by releasing a burst of compressed air at regular intervals to clean the filter bags, dislodging accumulated dust and maintaining consistent airflow. Unlike conventional filters, which may need frequent manual cleaning, the Pulse Jet Bag Filter operates automatically, reducing the need for labor-intensive maintenance. This results in lower operational costs and increased efficiency, as the system can maintain optimal performance without interruption.

Reduced Maintenance and Increased Durability

Maintenance can be a significant cost factor for many filtration systems. Traditional dust collection systems may require frequent maintenance, cleaning, or bag replacements, leading to expensive downtime. The Pulse Jet Bag Filter is engineered for durability, with high-quality, long-lasting filter bags that are designed to withstand the demanding conditions of recycling plants. Additionally, the pulse-jet cleaning technology extends the life of the filter bags, further reducing maintenance costs and increasing the overall efficiency of the system.

Compliance with Environmental Regulations

In many countries, recycling facilities are required to comply with strict environmental regulations to control emissions and limit air pollution. Failure to meet these regulations can lead to hefty fines, legal challenges, and damage to a company's reputation. The Pulse Jet Bag Filter is designed to meet or exceed these environmental standards, ensuring that recycling plants can operate in full compliance. By efficiently trapping harmful particles and preventing them from being released into the air, this filter helps companies reduce their environmental footprint and maintain compliance with local and international regulations.

Energy Efficiency and Cost-Effectiveness

In an era where sustainability and cost-efficiency are paramount, the Pulse Jet Bag Filter for Recycling Plants offers a smart solution. The system is designed to minimize energy consumption while maximizing filtration performance. The use of pulse-jet cleaning ensures that the system runs efficiently, reducing the need for additional energy-intensive processes. As a result, the filter helps recycling facilities reduce their operational costs while maintaining high filtration standards. Additionally, the extended lifespan of the filter bags reduces the need for frequent replacements, resulting in long-term savings for the facility.

Versatility for Various Recycling Applications

The Pulse Jet Bag Filter is versatile and adaptable to a wide range of recycling processes. Whether it's the recycling of paper, plastics, metals, or electronic waste, this filtration system is capable of handling diverse materials and processes with ease. The system can be customized to meet the specific requirements of each recycling plant, ensuring that the filtration system is optimized for maximum efficiency and performance.

Easy Installation and Integration

Installation of the Pulse Jet Bag Filter is simple and straightforward, designed to integrate seamlessly into existing recycling plant operations. Whether retrofitting an existing system or installing a new one, the filter can be easily incorporated into the facility without significant disruption. This ease of installation reduces downtime during the setup process and allows for quicker adoption of the new filtration system.

Improved Worker Safety and Health

Dust exposure is a significant concern in recycling plants, particularly in facilities that handle hazardous materials such as metals, plastics, and e-waste. The Pulse Jet Bag Filter plays a crucial role in mitigating these risks by capturing dust and particulates before they can become airborne. By maintaining a cleaner, healthier environment, the filter reduces the risk of respiratory problems and other health issues for workers, contributing to a safer and more comfortable workplace.

Contribution to Sustainable Operations

Sustainability is at the core of the recycling industry. By ensuring that dust and particulate matter are effectively captured and managed, the Pulse Jet Bag Filter for Recycling Plants helps facilities operate more sustainably. It contributes to cleaner air, reduced emissions, and a lower environmental impact, supporting the overall mission of recycling plants to minimize waste and protect the environment. Furthermore, the energy-efficient design and long-lasting components of the filter help reduce the carbon footprint of the facility.

Reliability and Consistency

Reliability is crucial for any industrial filtration system. The Pulse Jet Bag Filter is engineered to provide consistent, long-term performance, even in challenging environments. The advanced filtration technology ensures that the system continues to function at optimal levels, providing reliable dust collection and air purification throughout the operation. With its durable construction, low maintenance requirements, and high filtration efficiency, the Pulse Jet Bag Filter offers unmatched reliability for recycling plants.

Conclusion

In summary, the Pulse Jet Bag Filter for Recycling Plants is a state-of-the-art solution that addresses the unique challenges faced by recycling facilities. With its high-efficiency dust collection, pulse-jet cleaning technology, reduced maintenance needs, and environmental compliance, this filter is designed to optimize the performance of recycling operations. It contributes to cleaner air, safer working conditions, and more sustainable practices, while also offering energy efficiency and cost savings. Whether you're looking to improve air quality, comply with environmental regulations, or reduce operational costs, the Pulse Jet Bag Filter is the ideal choice for your recycling facility.

By investing in this advanced filtration solution, recycling plants can not only enhance their operational efficiency but also play a crucial role in protecting the environment and supporting the health and well-being of their workforce. Choose the Pulse Jet Bag Filter for Recycling Plants to ensure cleaner, safer, and more sustainable operations today.