The Primary Impact Crusher is a crucial machine in the initial stage of material processing, designed to break down large rocks and raw materials into smaller, manageable sizes. Its primary role is to handle materials such as limestone, granite, and dolomite, ensuring efficient size reduction for further processing or direct use in industries like mining, quarrying, construction, and cement production.

Equipped with a robust rotor and durable impact hammers, the machine uses high-speed impacts to crush materials effectively. Adjustable settings allow precise control over the final product size, making it versatile for various applications. Built with high-quality materials, the crusher is engineered to withstand heavy-duty operations and minimize maintenance costs.

At Sediroglu International, our Primary Impact Crushers are designed to maximize productivity while ensuring energy efficiency and ease of use. They are suitable for large-scale infrastructure projects, aggregate production, and industrial material processing. By delivering consistent performance and high-quality output, these machines play an essential role in optimizing production processes and meeting the demands of modern industries.

Choose Sediroglu International for reliable, innovative, and efficient crushing solutions tailored to your specific needs.

The Primary Impact Crusher is a robust and reliable machine designed for heavy-duty crushing operations. To ensure its optimal performance and prolong its lifespan, regular maintenance and timely repairs are essential.

When Should Maintenance Be Performed?

Daily Inspections:

Operators should conduct daily visual inspections to check for wear on critical components such as the rotor, impact hammers, and wear plates. Any visible cracks, loosened bolts, or unusual sounds should be addressed immediately.

Routine Maintenance:

Weekly Checks: Inspect the lubrication system, bearings, and hydraulic systems. Ensure all moving parts are adequately greased to minimize friction.

Monthly Inspections: Examine the crusher’s internal parts for wear and tear. Replace worn-out components like liners and hammers to maintain efficiency.

Major Overhauls:

Depending on usage, a comprehensive inspection and servicing should be performed every 6-12 months. This includes checking the rotor alignment, tightening all bolts, and replacing critical components if needed.

Why Regular Maintenance Matters

Neglecting maintenance can lead to unexpected breakdowns, reduced performance, and higher repair costs. At Sediroglu International, we recommend following a strict maintenance schedule and using genuine parts for repairs to ensure maximum efficiency and reliability.

With proper care, your Primary Impact Crusher will deliver consistent performance and a longer operational life, ensuring seamless production processes.

The Primary Impact Crusher is a versatile machine used in a wide range of industrial facilities for processing large-sized materials into smaller, uniform sizes. Its high efficiency and reliability make it an essential component in numerous industries.

Facilities Where Primary Impact Crushers Are Used:

Quarries:

Primary Impact Crushers are a key part of aggregate production in quarries. They process raw materials like limestone, granite, and dolomite, transforming them into high-quality aggregates used in construction projects.

Mining Operations:

In mining facilities, these crushers handle ores and rocks, preparing them for further processing or direct use. Their ability to crush hard and abrasive materials ensures they meet the demands of mining operations efficiently.

Cement Plants:

Cement production heavily relies on Primary Impact Crushers to crush materials like limestone and clay. These machines provide the consistency needed for high-quality cement manufacturing.

Construction and Infrastructure Projects:

From road construction to large-scale infrastructure developments, Primary Impact Crushers produce the aggregates necessary for concrete and asphalt production.

Recycling Plants:

They are also used in recycling facilities to process demolition waste, turning it into reusable materials.

At Sediroglu International, our Primary Impact Crushers are designed to meet the needs of these industries, delivering exceptional performance and durability in even the most demanding environments.

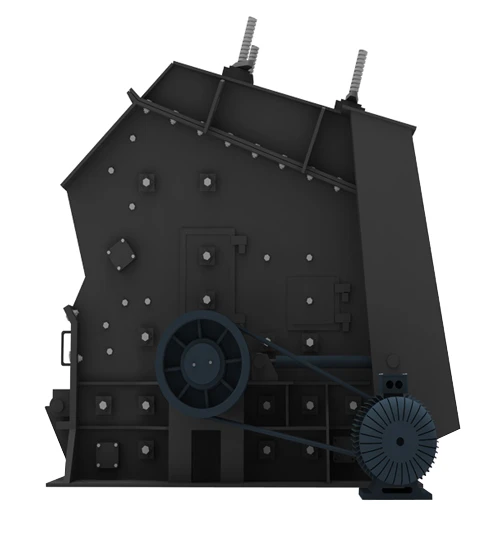

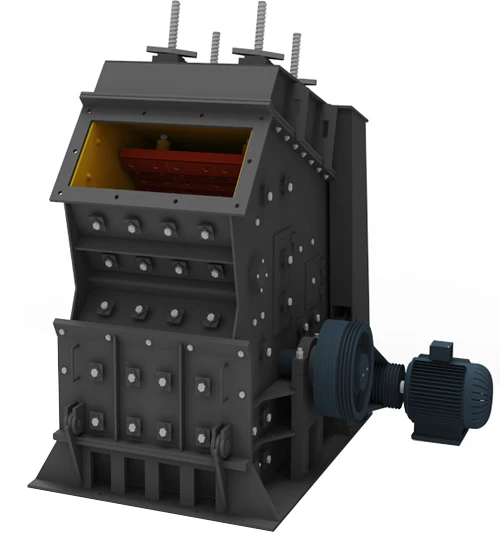

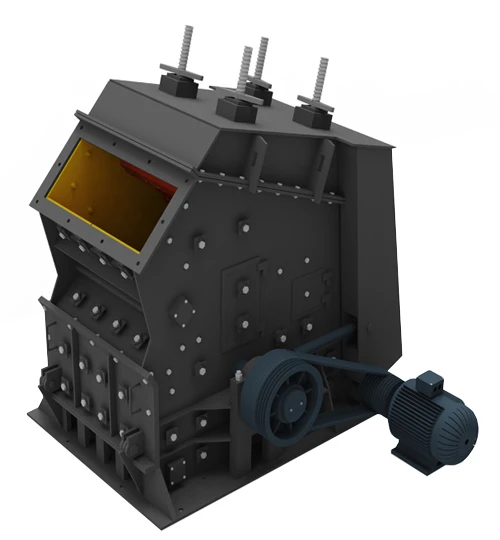

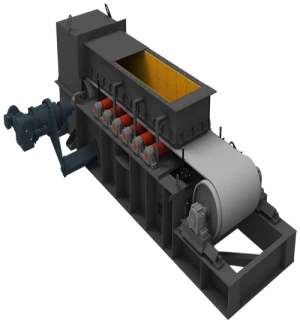

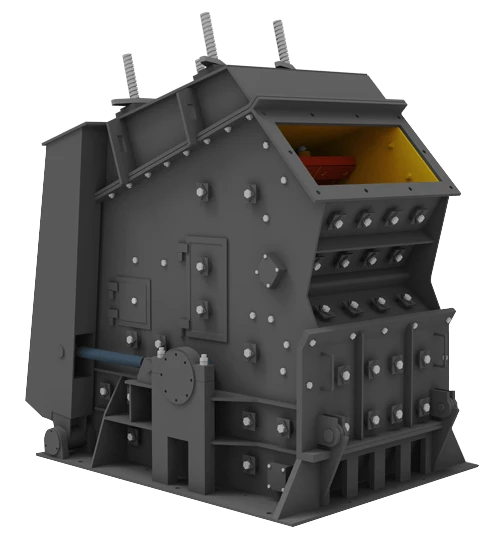

The Primary Impact Crusher is a robust and efficient machine designed for crushing large-sized materials into smaller, manageable pieces. Its design incorporates several critical components that work together to ensure optimal performance and reliability. Below are the main parts of a Primary Impact Crusher:

1. Rotor

The rotor is the heart of the crusher. It consists of a heavy steel shaft and attached hammers or blow bars. The rotor rotates at high speeds, delivering the impact force needed to crush the materials.

2. Blow Bars (Hammers)

These are wear-resistant steel or alloy bars mounted on the rotor. Blow bars strike the incoming material, breaking it into smaller pieces. They are designed for durability and efficiency.

3. Impact Plates (Breaker Plates)

Located inside the crushing chamber, impact plates absorb the force of the material as it is thrown by the rotor. They also contribute to further breaking down the material and help achieve the desired size.

4. Crushing Chamber

The chamber houses the rotor, blow bars, and impact plates. It is designed to maximize material flow and ensure efficient crushing.

5. Feed Opening

This is the entry point for materials. A wide feed opening allows the crusher to handle large-sized materials efficiently.

6. Hydraulic Adjustment System

Modern crushers often include a hydraulic system to adjust the gap between the rotor and impact plates. This feature allows operators to control the size of the output material with precision.

7. Frame and Housing

The outer structure supports all internal components and provides protection. It is built from heavy-duty materials to ensure stability and durability during operation.

8. Bearings and Drive System

The bearings support the rotor and ensure smooth rotation. The drive system, typically powered by an electric motor, transfers energy to the rotor.

9. Lubrication System

A lubrication system reduces friction and wear on moving parts, prolonging the machine’s lifespan and ensuring efficient operation.

At Sediroglu International, our Primary Impact Crushers are engineered with high-quality components, ensuring durability, efficiency, and reliability in demanding applications.