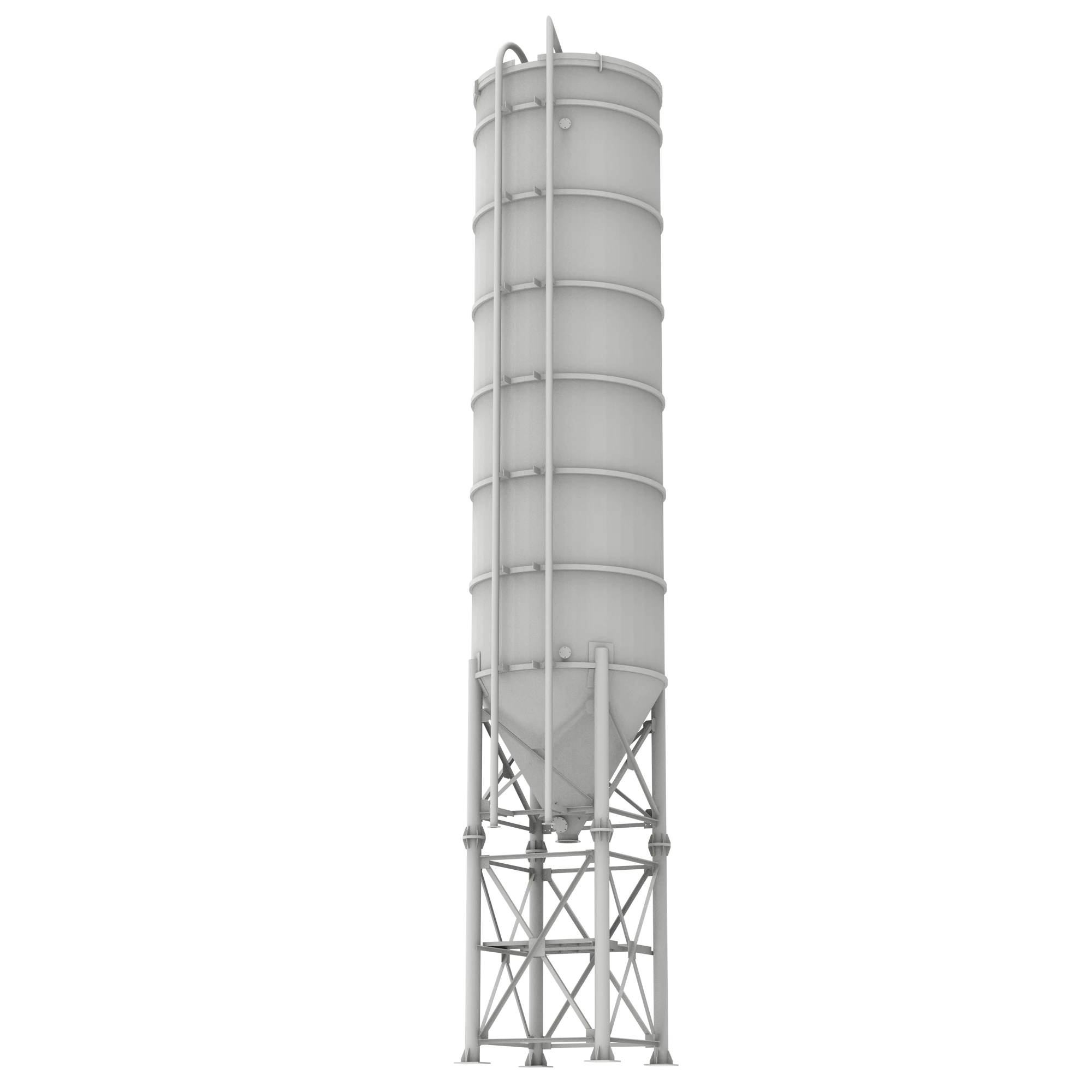

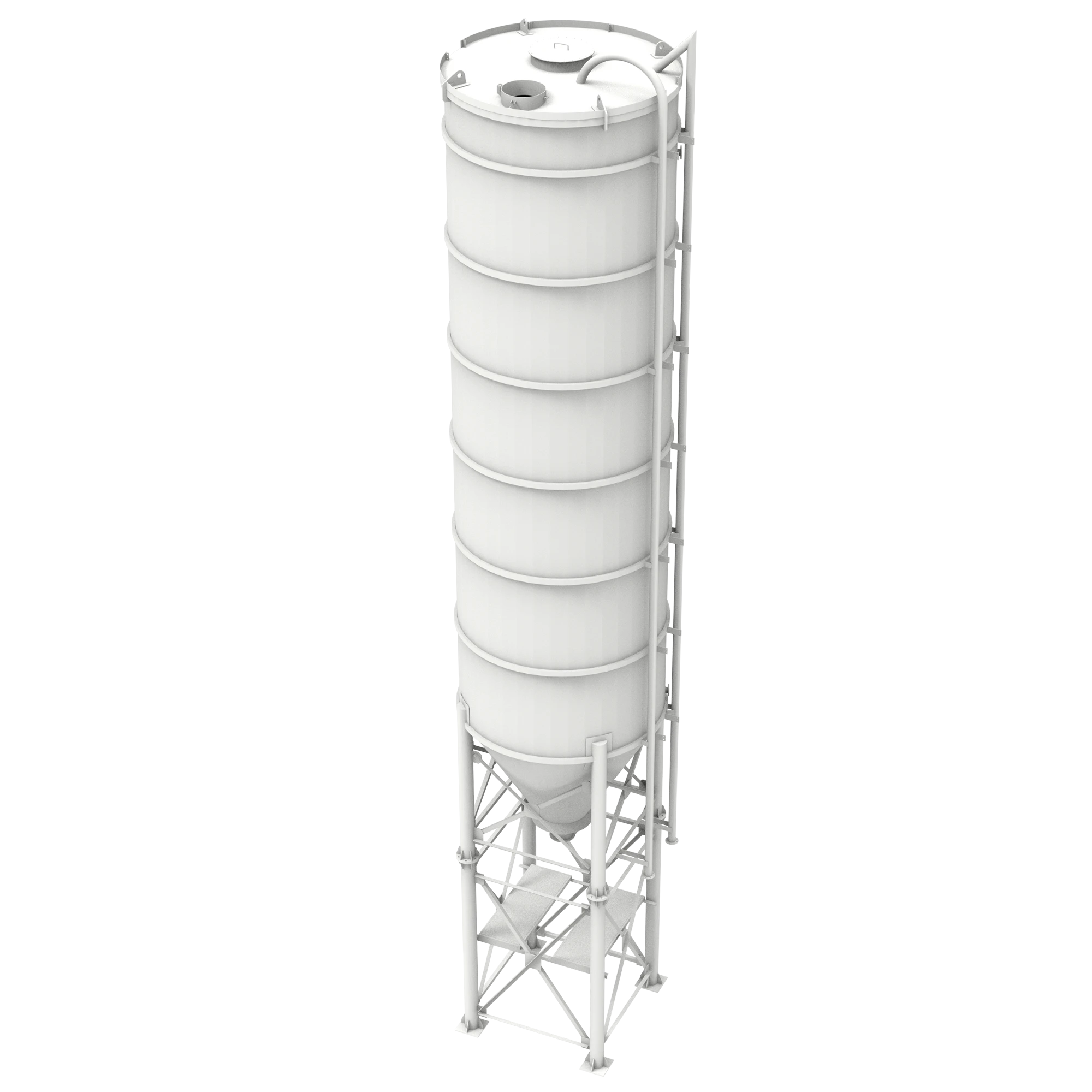

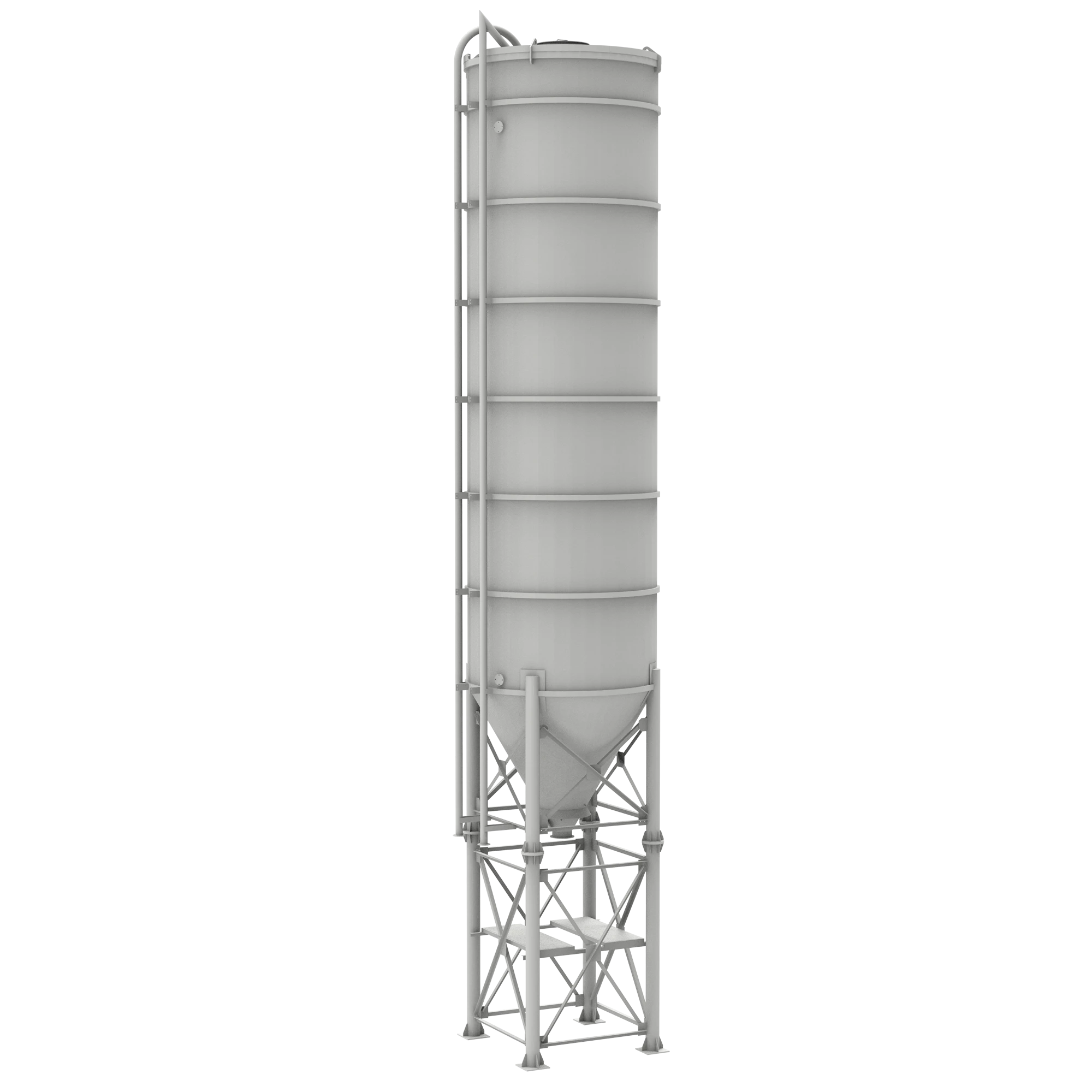

"Concrete Batching Plant Storage Silos are essential for the efficient and organized storage of various raw materials, such as cement, aggregates, and additives, that are required in the production of concrete. These silos are designed to support large-scale operations by offering a secure and reliable solution for material storage, ensuring a steady and uninterrupted supply for mixing processes. Manufactured with high-quality materials and advanced technology, these silos are equipped with features that allow easy monitoring of material levels, ensuring accurate batching. They play a crucial role in maintaining the smooth operation of concrete batching plants, significantly improving production efficiency. The durable and robust construction of Concrete Batching Plant Storage Silos ensures long-lasting performance and minimal maintenance requirements. Furthermore, their modular design allows for flexibility in installation, making them suitable for both small and large batching plants. With superior storage capacity, these silos are capable of holding substantial amounts of material, which helps reduce downtime, optimize material usage, and lower operational costs. Designed to withstand challenging environmental conditions, these silos provide a reliable solution that can operate continuously without interruption. Their easy-to-operate systems enhance the overall productivity of concrete production plants by minimizing the risk of material wastage and ensuring that raw materials are available when needed. With their high-efficiency design, Concrete Batching Plant Storage Silos are a vital component for any plant looking to improve its productivity, reduce waste, and streamline its operations, while maintaining the highest standards of quality control in concrete production."

"Industrial Silos for Concrete Plants are crucial components designed to enhance the efficiency and productivity of large-scale concrete production operations. These silos are engineered specifically to store a wide range of materials, such as cement, aggregates, and other additives, essential for the concrete mixing process. By providing a safe and organized storage solution, Industrial Silos for Concrete Plants help minimize downtime, reduce material wastage, and ensure a continuous supply of materials for uninterrupted operations.

Constructed with durable, high-quality materials, Industrial Silos for Concrete Plants are built to withstand the rigors of harsh industrial environments. Their robust design ensures that the stored materials remain safe and secure, preventing contamination and ensuring that only the highest-quality concrete is produced. Whether used for storing bulk cement or aggregates, these silos play an essential role in maintaining the smooth functioning of the plant, allowing operators to focus on other aspects of production.

In addition to their durability, Industrial Silos for Concrete Plants are equipped with advanced monitoring and control systems. These systems allow operators to track the level of stored materials in real-time, ensuring optimal inventory management and preventing overfilling or running out of materials. The precise monitoring capabilities of these silos also contribute to the overall accuracy of the batching process, ensuring that each batch of concrete is made to the correct specifications.

One of the key benefits of Industrial Silos for Concrete Plants is their ability to optimize space utilization. These silos are designed to have a compact footprint while offering large storage capacities, making them ideal for plants with limited space. Their modular design allows for easy installation and integration into existing plant setups, further enhancing their flexibility and adaptability.

Moreover, Industrial Silos for Concrete Plants are designed with maintenance in mind. Their user-friendly features and accessible components make routine maintenance tasks, such as cleaning and inspection, quick and efficient. This helps to reduce downtime and keep the plant running smoothly, ensuring consistent production levels and minimizing costly disruptions.

In addition to enhancing productivity and efficiency, Industrial Silos for Concrete Plants also contribute to the overall sustainability of concrete production. By optimizing material storage and minimizing waste, these silos help reduce the environmental impact of concrete plants. Their ability to accurately manage material inventories ensures that raw materials are used efficiently, reducing the need for excess procurement and transportation, which in turn lowers the plant's carbon footprint.

Overall, Industrial Silos for Concrete Plants are an essential investment for any concrete production facility looking to improve efficiency, reduce costs, and enhance the quality of their product. With their durable construction, advanced monitoring capabilities, and space-saving design, these silos are an indispensable part of modern concrete batching plants, helping to streamline operations and increase profitability."

Concrete Storage Silos for Batching Plants: Efficient Solutions for Cement and Aggregate Storage

In the world of construction and concrete production, efficiency is key to delivering high-quality projects on time and within budget. One of the most critical components in concrete batching plants is the Concrete Storage Silos for Batching Plants. These silos play a crucial role in the proper storage and preservation of cement and aggregates, ensuring that materials are kept dry, free from contaminants, and ready for use when needed.

Concrete batching plants require a reliable and efficient system to handle large quantities of raw materials such as cement, sand, and aggregates. Concrete Storage Silos for Batching Plants are specifically designed to meet this need, offering optimized storage space, durability, and easy access to the materials that are essential for concrete production. By utilizing high-quality silos, plant operators can ensure consistent material flow, minimize waste, and streamline the entire batching process.

These silos are equipped with advanced features that make them ideal for industrial applications. For instance, the Concrete Storage Silos for Batching Plants are built with corrosion-resistant materials, ensuring that the storage capacity remains intact even under harsh weather conditions. The silos are designed for high capacity, allowing large amounts of cement and aggregates to be stored efficiently. The use of state-of-the-art technology also ensures that the materials are automatically fed into the mixing plant, reducing manual labor and improving operational efficiency.

One of the key benefits of Concrete Storage Silos for Batching Plants is their ability to maintain the quality and consistency of the stored materials. Cement, in particular, is highly sensitive to moisture, and exposure to water can result in clumping and reduced performance. With specialized storage systems, these silos prevent moisture ingress, keeping the cement in optimal condition. This helps maintain the quality of the concrete produced, ensuring strong and durable end products.

Moreover, Concrete Storage Silos for Batching Plants contribute to improved safety in the workplace. With automated systems for material handling, there is less need for workers to manually load and unload materials, reducing the risk of injury and improving overall safety standards. The silos are designed with safety features such as pressure relief valves and dust control systems, ensuring that the batching process remains smooth and safe for all involved.

In addition to their practical advantages, the Concrete Storage Silos for Batching Plants are designed with energy efficiency in mind. By incorporating features like high insulation properties and advanced airflow systems, these silos help reduce energy consumption and lower operational costs. This makes them an ideal solution for companies looking to improve their bottom line while maintaining high production standards.

Overall, Concrete Storage Silos for Batching Plants are an essential component in modern concrete production. They offer numerous benefits, including reliable storage, improved material handling, increased safety, and energy efficiency. Whether for small-scale construction projects or large industrial applications, these silos are designed to meet the demands of the concrete batching industry. With the right system in place, businesses can ensure the efficient storage and handling of materials, ultimately contributing to the success of their projects and enhancing their operational efficiency.

By investing in Concrete Storage Silos for Batching Plants, companies can improve the quality of their concrete, reduce material waste, and ensure that their batching plants run smoothly and efficiently. With the right choice of silo system, concrete production becomes more streamlined, cost-effective, and environmentally friendly. These silos are truly a valuable asset to any batching plant, helping businesses stay competitive and deliver superior concrete products to meet the needs of their clients.