Apron feeders are essential equipment for industries that handle large volumes of heavy and abrasive materials. Designed to operate in challenging conditions, these feeders provide a reliable and efficient solution for transferring bulk materials such as ores, coal, aggregates, and other heavy-duty materials. Their rugged construction ensures durability and long-term performance, even under the harshest environments.

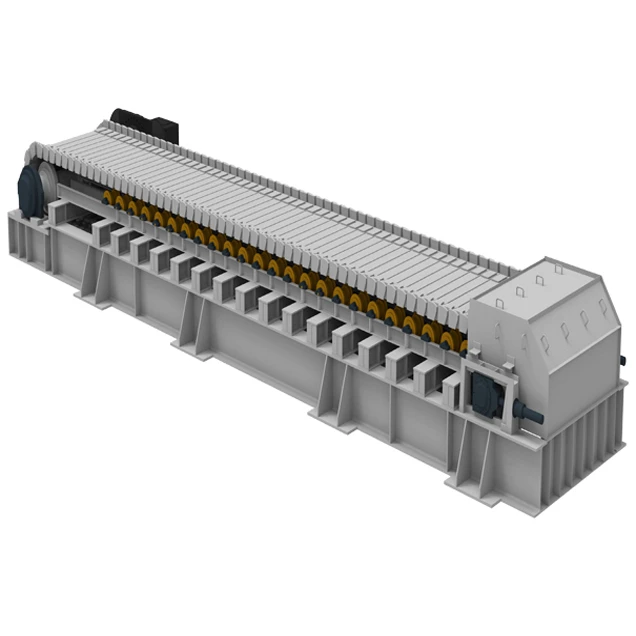

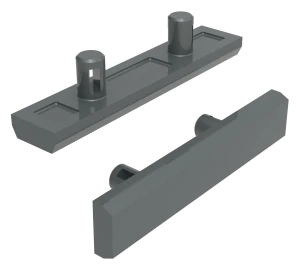

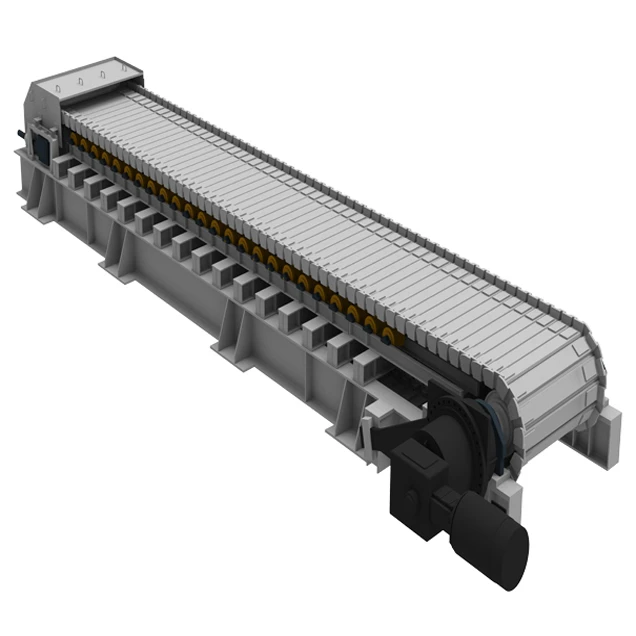

High-performance apron feeders are engineered to deliver precision and consistency in material handling processes. They feature heavy-duty steel pans that are securely connected to a chain-driven system, enabling smooth and continuous material flow. This design not only prevents spillage but also minimizes wear and tear, reducing downtime and maintenance costs.

These feeders are widely used in mining, aggregate processing, cement manufacturing, and coal handling facilities. In mining, apron feeders are essential for transferring large chunks of ore to crushers or conveyors. In aggregate operations, they handle stones and gravel with ease, ensuring a steady supply to processing equipment. The robust design makes them suitable for handling abrasive and high-impact materials.

Apron feeders also enhance operational efficiency by allowing precise feed rate adjustments to match the needs of downstream equipment. This flexibility ensures seamless integration into various industrial processes, making them a versatile choice for heavy-duty applications.

Sediroglu International provides high-performance apron feeders tailored to meet the demands of modern industries. Combining innovative engineering with top-quality materials, these feeders deliver exceptional reliability and productivity, ensuring optimal performance in all conditions.

Steel apron feeders are essential components in industries that require reliable and efficient material handling solutions for heavy and abrasive materials. Designed to transport bulk materials like ores, coal, and rock, these feeders play a vital role in mining and aggregate processing. They provide a robust and durable solution for moving materials from storage units such as hoppers or bins to crushers, conveyors, or other processing equipment.

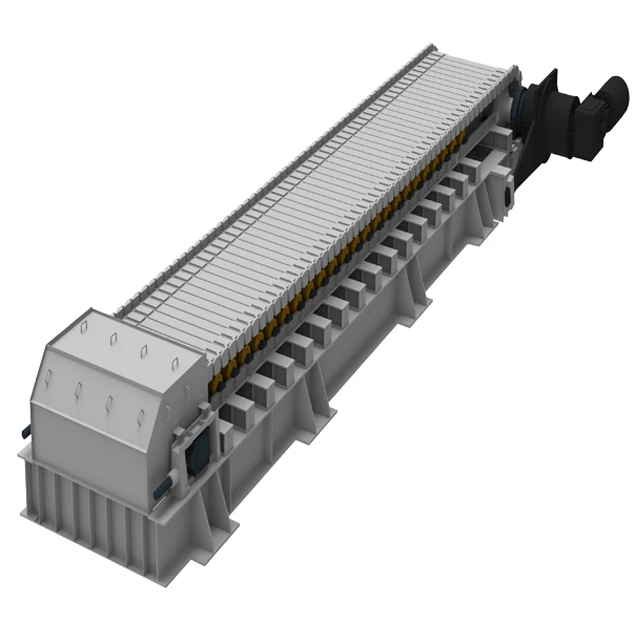

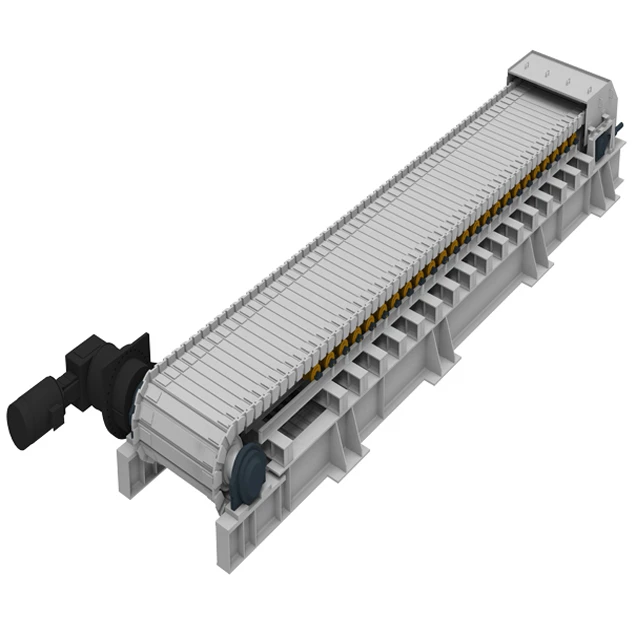

The core principle of steel apron feeders lies in their ability to handle challenging materials under harsh working conditions. The equipment is equipped with heavy-duty steel pans connected to a chain-driven system. This ensures smooth and continuous operation even when transporting the toughest materials. The design incorporates rugged construction and wear-resistant components to enhance the lifespan and reliability of the system, reducing downtime and maintenance costs.

In mining operations, steel apron feeders are indispensable for transferring extracted ores to processing plants. Their ability to handle lumpy, abrasive materials with precision ensures a steady flow of materials, which is critical to maintaining production efficiency. Similarly, in aggregate processing, they are used for handling large stones and gravel, enabling seamless feeding into crushers and screens.

These feeders are not limited to mining and aggregate industries. They are also widely used in cement production facilities for moving raw materials like limestone and clay. In coal power plants, steel apron feeders ensure a consistent supply of fuel to boilers and processing equipment. Their application extends to ports and bulk material handling facilities, where they assist in loading and unloading bulk cargo efficiently.

Sediroglu International offers state-of-the-art steel apron feeders engineered for demanding industrial applications. The company's solutions prioritize durability, precision, and performance, making them a preferred choice for clients across the globe. By combining innovative design with superior material quality, Sediroglu International ensures its feeders deliver long-term reliability and high productivity.

The advanced design of Sediroglu International’s steel apron feeders includes features like adjustable feed rates, customizable lengths, and compatibility with various material handling systems. These capabilities make them suitable for a wide range of applications, ensuring operational flexibility and efficiency. The feeders are engineered to minimize spillage and handle heavy impact loads, which are common in bulk material handling.

Durable steel apron feeders not only improve productivity but also contribute to safer working environments. They eliminate the risk of material blockages, ensuring smooth and consistent operations. The use of high-strength steel components and wear-resistant liners further enhances their ability to withstand extreme conditions, making them a reliable choice for industries dealing with tough materials.

Sediroglu International’s expertise in material handling solutions ensures that its steel apron feeders meet the diverse needs of its clients. Whether it’s mining, aggregates, cement, or bulk handling, these feeders provide unmatched performance, reducing operational costs and downtime while maximizing throughput.

If your operation requires a heavy-duty material handling solution that prioritizes durability and efficiency, Sediroglu International’s steel apron feeders are the ideal choice. Designed with precision and built for performance, they deliver unmatched reliability for the most demanding industrial environments.

Steel apron feeders are indispensable in industries requiring the efficient handling of heavy, abrasive, and large-sized materials. Designed to ensure seamless material flow between storage units, crushers, and conveyors, these feeders provide exceptional reliability and durability. Their robust construction makes them ideal for mining, aggregate processing, cement production, and other demanding applications.

Engineered with high-strength steel pans linked to a chain-driven system, apron feeders efficiently transfer materials such as ores, coal, and aggregates. This sturdy design minimizes spillage and resists wear from abrasive materials, ensuring consistent performance over extended periods. Adjustable feed rates further enhance flexibility, enabling smooth integration with crushers and conveyors for optimal processing efficiency.

One of the key advantages of apron feeders is their ability to handle extreme conditions, from heavy-impact loads to varying moisture levels. In mining operations, they serve as critical equipment for delivering large chunks of material to primary crushers, ensuring uninterrupted production. Similarly, in aggregate and cement plants, apron feeders maintain steady material flow to conveyors and other downstream systems, supporting continuous operations.

Sediroglu International's steel apron feeders are crafted to deliver unparalleled reliability and performance. Combining advanced engineering with premium materials, they are designed to withstand the toughest industrial environments. Whether feeding crushers or conveyors, Sediroglu's apron feeders optimize productivity, reduce downtime, and enhance overall operational efficiency.

Industrial steel apron feeders are essential in heavy-duty operations like mining and material processing, where they handle large, abrasive, and heavy materials. These feeders are designed to withstand extreme conditions, efficiently transporting ores, coal, and aggregates from storage bins to crushers, conveyors, or other processing equipment. Their durable steel construction ensures long-term reliability, minimizing maintenance costs and downtime.

In mining operations, steel apron feeders provide consistent and controlled material flow, crucial for feeding primary crushers and maintaining smooth downstream operations. These feeders excel in managing large, lumped materials while preventing spillage and reducing wear and tear. Their robust design makes them ideal for challenging environments, ensuring high performance even with varying material sizes and moisture content.

Sediroglu International offers state-of-the-art industrial steel apron feeders that are engineered for optimal durability and efficiency. With adjustable feed rates and heavy-duty construction, they integrate seamlessly into mining and processing systems, optimizing productivity and streamlining material handling. These feeders are a vital component in ensuring operational efficiency and minimizing disruptions in mining and material processing facilities.