Dust Collection System for Zinc Facilities

Working Principle

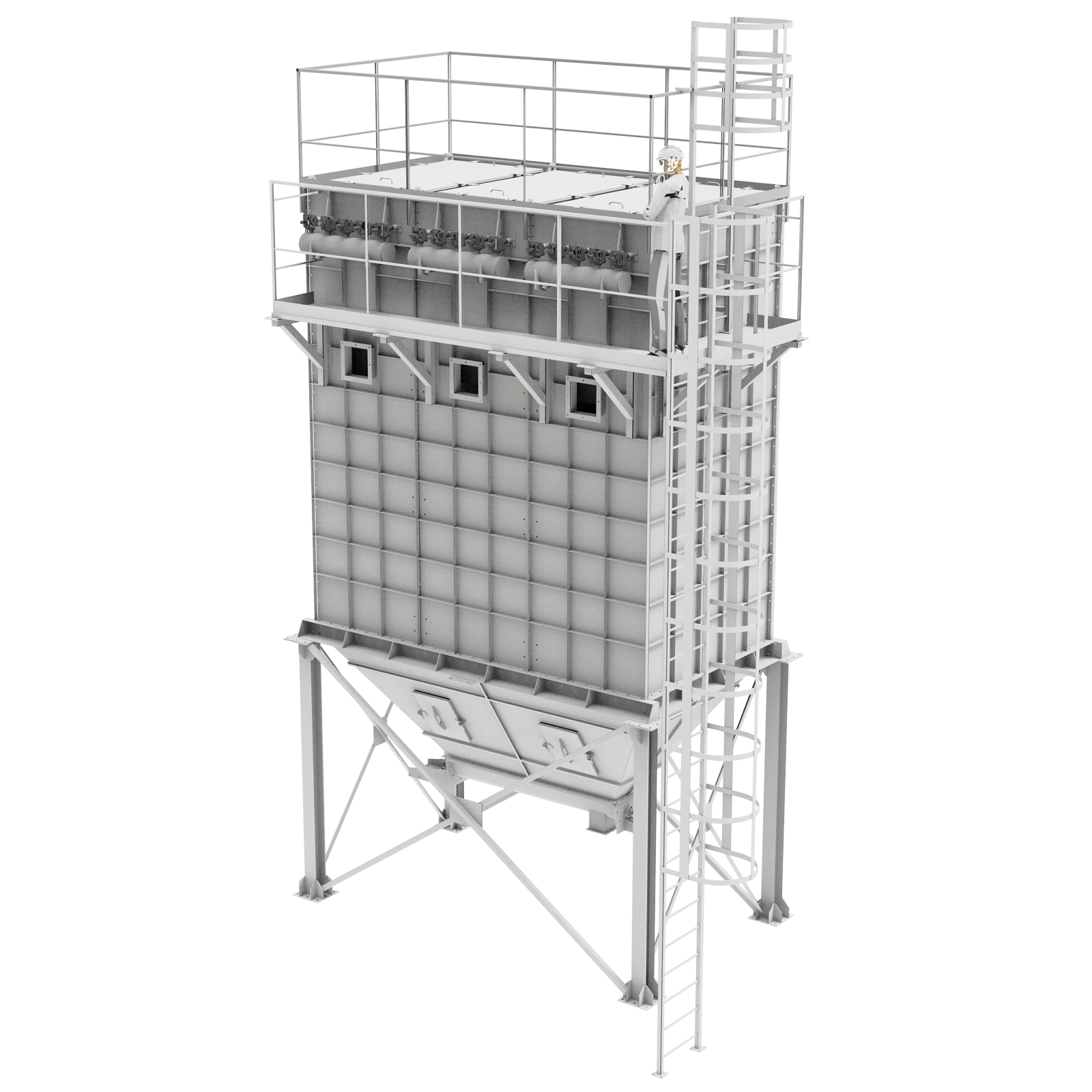

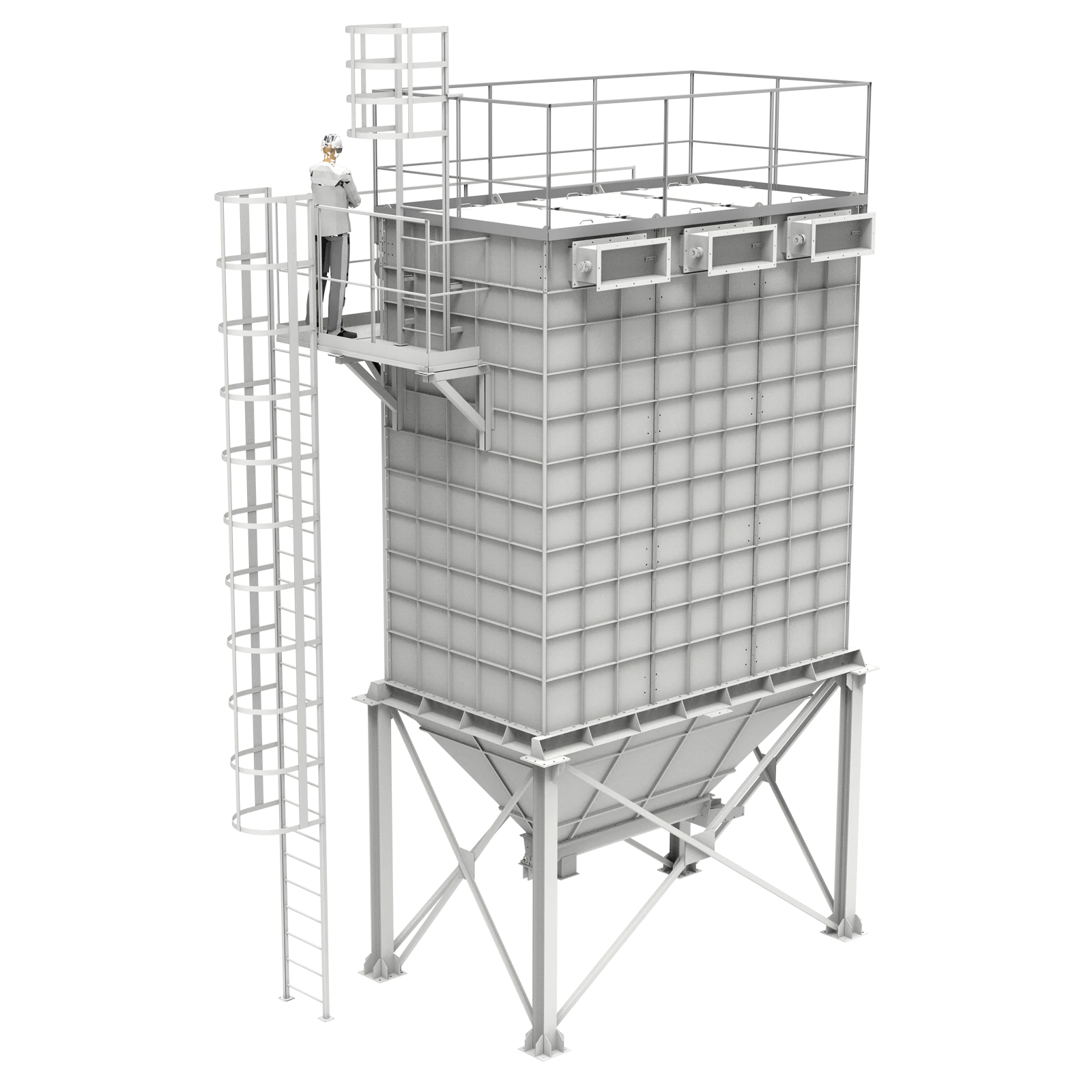

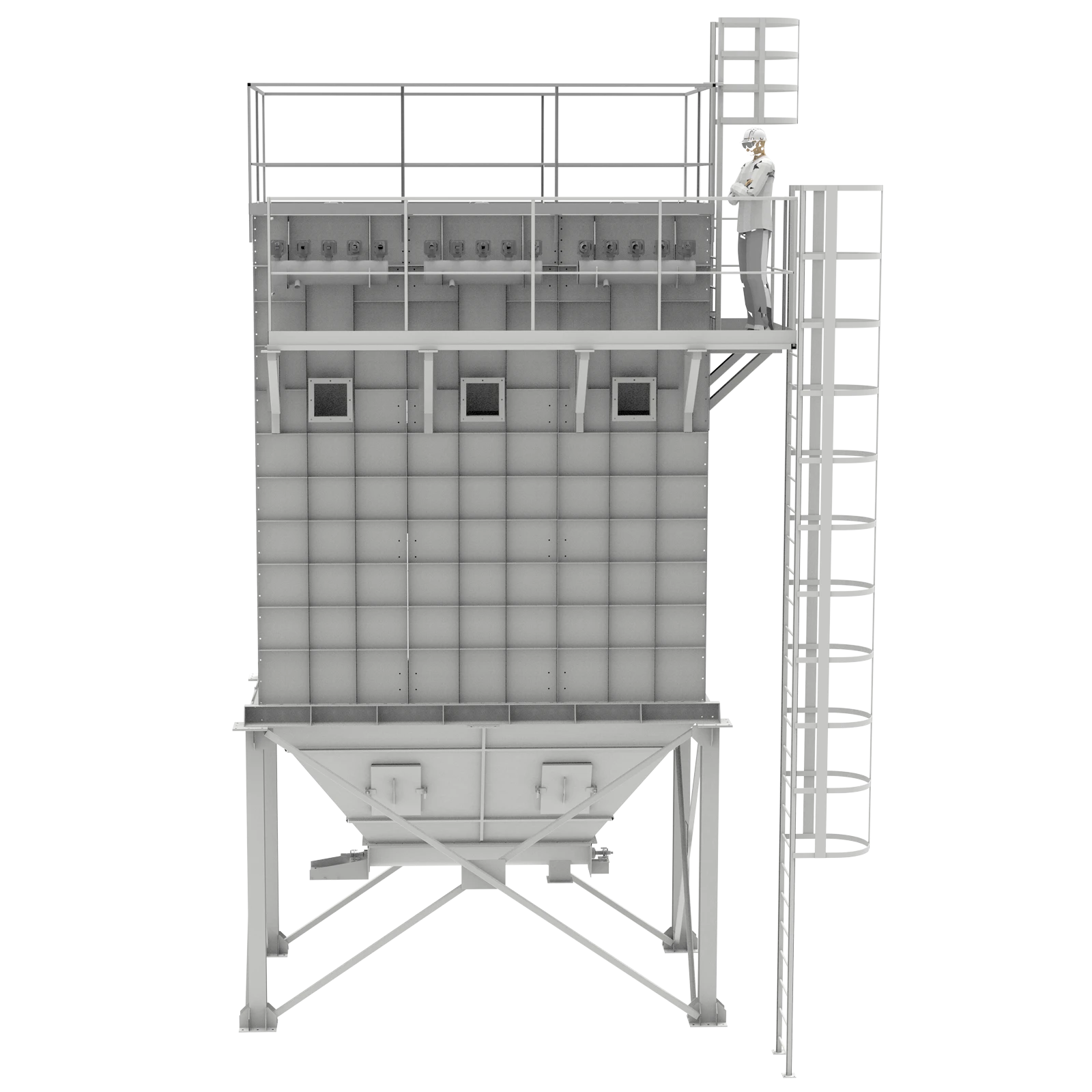

The working principle of the Jet Pulse Bag House Filter involves the use of high-efficiency filter bags to capture dust, particulates, and harmful emissions from industrial processes. As air passes through the filter, particles are trapped on the surface of the bags. Periodically, a pulse of compressed air is applied to clean the bags, dislodging accumulated dust, and maintaining optimal airflow and filtration performance. This ensures consistent dust control and air quality in zinc production facilities.

Clean Air Technology for Zinc Processing Facilities

Technical Specifications

The Jet Pulse Bag House Filter features high-efficiency filter bags designed to capture fine dust and particulates. It utilizes a pulse-jet cleaning system to maintain optimal airflow and performance. The filter is made from durable materials, ensuring long-lasting operation with minimal maintenance. It is equipped with a reliable dust collection system, capable of handling high volumes of air, and is designed for easy installation and integration into zinc production facilities, ensuring environmental compliance and improved air quality.

Air Filtration for Zinc Processing Facilities

Application Areas

The Jet Pulse Bag House Filter offers numerous advantages, including high dust collection efficiency, low maintenance, and extended filter life. Its pulse-jet cleaning system ensures continuous optimal airflow, reducing downtime. The filter’s durable construction makes it reliable for long-term use in demanding zinc production environments. Additionally, it ensures compliance with environmental regulations by effectively controlling emissions and improving air quality, leading to a safer and cleaner work environment. Its cost-effectiveness and energy-efficient design further enhance operational savings.

Sediroglu International offers a comprehensive range of advanced filtration solutions designed specifically for zinc production facilities. Our advanced filtration systems are engineered to address the unique challenges faced by zinc plants, including the control of dust, particulates, and harmful emissions that are often generated during the manufacturing process. With a deep commitment to environmental sustainability, Sediroglu International’s filtration technologies provide exceptional air quality management while ensuring compliance with global environmental standards.

Key Features of Our Advanced Filtration Solution for Zinc Production:

-

Enhanced Dust Control:

Our filtration systems excel at capturing even the finest dust particles and particulates that are common in zinc production. By effectively controlling dust emissions, we help ensure cleaner air, improved visibility, and a safer working environment for your team.

-

Environmental Compliance:

Zinc production is a heavily regulated industry when it comes to air pollution control. Sediroglu International’s filtration solutions are designed to meet or exceed international environmental standards. This ensures that your facility remains fully compliant with air quality regulations, avoiding costly fines and reputational damage associated with environmental violations.

-

Energy Efficiency:

Sediroglu International’s filtration systems are engineered to be energy-efficient, helping you to reduce operational costs while maintaining high-performance standards. With low energy consumption and optimal airflow management, our solutions provide long-term cost savings without compromising on efficiency.

-

Reliability and Durability:

We understand that reliability is crucial in industrial environments. Our filters are built to last, offering long operational lifespans with minimal maintenance requirements. This means fewer disruptions to your production process and a higher return on investment.

-

Tailored Solutions:

Every zinc production facility is unique, which is why Sediroglu International offers customized filtration solutions to meet your specific needs. Whether your facility is dealing with higher levels of emissions or you require specialized dust control measures, we work closely with you to design a filtration system that fits your operational requirements.

Benefits for Zinc Production Facilities:

-

Improved Workplace Safety:

Our filtration systems play a vital role in improving the air quality inside zinc production plants. By controlling airborne particles and preventing dust from accumulating, we help create a healthier environment for your workforce, reducing the risk of respiratory issues and enhancing overall safety.

-

Lower Maintenance Costs:

With Sediroglu International’s advanced filtration systems, zinc plants benefit from reduced maintenance costs. Our systems are designed with durable components that are built to withstand the demanding conditions of industrial environments, requiring less frequent maintenance and replacement.

-

Increased Operational Efficiency:

By ensuring a clean and efficient filtration process, Sediroglu International helps zinc production facilities run smoother and more effectively. The enhanced dust control reduces downtime caused by clogged or inefficient filtration systems, allowing your facility to operate at peak efficiency.

-

Sustainable Production:

At Sediroglu International, we prioritize sustainability in all our solutions. Our filtration systems are not only designed to protect the environment but also to support the long-term viability of your zinc production operations. By reducing emissions and improving energy efficiency, our systems help you achieve your sustainability goals.

-

Global Expertise and Support:

Sediroglu International brings decades of expertise in industrial filtration technology, and we pride ourselves on offering excellent customer service and technical support. Our team is available to assist you at every step, from system design to installation and ongoing maintenance, ensuring that your filtration system continues to perform at its best throughout its lifespan.

Why Choose Sediroglu International for Your Zinc Production Filtration Needs?

-

Proven Track Record:

With years of experience serving industries worldwide, Sediroglu International has built a reputation for delivering high-quality, reliable filtration solutions. We have worked with numerous zinc production facilities to improve air quality, reduce emissions, and ensure environmental compliance.

-

Innovative Technology:

We utilize the latest advancements in filtration technology to ensure that our systems are at the forefront of industry standards. Our research and development team continuously strives to improve the efficiency and effectiveness of our filtration systems, providing your facility with cutting-edge solutions.

-

Customizable Filtration Systems:

We understand that no two facilities are alike, which is why our filtration systems can be tailored to meet the specific needs of your zinc production operation. Whether you need a simple dust collector or a more complex filtration solution, we can provide a system that is perfectly suited to your needs.

-

Sustainable and Cost-Effective Solutions:

Sediroglu International’s filtration systems offer the perfect balance of environmental responsibility and cost efficiency. By reducing operational costs, enhancing productivity, and promoting sustainability, our solutions contribute to the overall success and longevity of your zinc production facility.

-

Comprehensive Support Services:

From initial consultation and system design to installation, maintenance, and troubleshooting, Sediroglu International provides end-to-end support. We ensure that your filtration system runs optimally, and we are always ready to assist you with any technical concerns.

Conclusion:

Sediroglu International’s advanced filtration solutions for zinc production facilities are designed to address the growing need for cleaner, safer, and more sustainable industrial operations. With our high-performance systems, zinc production plants can effectively manage air quality, meet regulatory requirements, and improve the safety and well-being of their workforce. By choosing Sediroglu International, you’re not only investing in a top-tier filtration system but also in the future success of your zinc production operation.

Whether you're looking to reduce emissions, enhance air quality, or ensure environmental compliance, Sediroglu International is the trusted partner you can rely on for cutting-edge, efficient, and customizable filtration solutions. Let us help you create a cleaner, safer, and more efficient zinc production environment.

×

![]()

The Chromium Steel Cooling Plate is essential for efficient heat dissipation in cement mills. Manufactured with high durability and precision, SEDIROGLU INTERNATIONAL delivers reliable spare parts that extend equipment life and en...

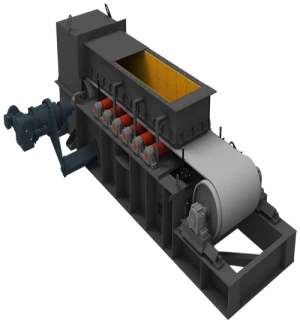

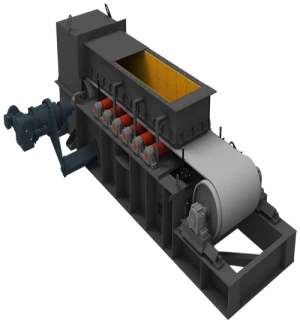

Sediroglu International’s Belt feeders are essential for precise and continuous material handling, designed to withdraw fine or wet materials from hoppers, bins, or stockpiles. They ensure a steady feed rate to equipment such as s...

At SEDIROGLU INTERNATIONAL, we provide high-quality spare parts for cement mills, including the Grate Holder. These parts are essential for ensuring optimal performance and longevity of your cement mill. Our grate holders are manu...